The 30 Day MBA (43 page)

Authors: Colin Barrow

The steps in the critical planning method process are:

- Identify the events.

- Decide on the sequence in which they must be carried out.

- Draw the network.

- Calculate the completion time for each event.

- Identify the longest and hence critical path.

- Keep the chart updated as events unwind.

Programme evaluation and review technique (PERT) and an activity network, also known as an âactivity-on-node diagram', are more sophisticated forms of CPM that allow for a degree of randomness in activity start and completion times.

Linear programming

In 1947, George Dantzig, an American mathematician, developed an algorithm (a mathematical technique) that could help resolve problems involving operational constraints. His algorithm could, for example, help with situations where several products could be produced, but materials, labour or machine capacity is insufficient to make all that's demanded â the challenge in that last case being to decide what mix of products can be produced that will make the maximum profit and then plan accordingly. Unfortunately, the iterative nature of producing solutions using Dantzig's algorithm proved so tedious that until cheap computers arrived it remained an academic idea of interest only to mathematics students.

The Dantzig algorithm comprises an objective, the quantity to be optimized, for example profit, nutrient content, water flow or production of one particular product out of several, and any variables and constraints on them, for example a certain minimum amount of water must flow.

Excel incorporates a Solver add-in feature to solve standard linear programming problems. It is not usually installed when Excel is first loaded so to add this facility:

- Select the menu option Tools | Add_Ins (you will need your original installation disk).

- From the dialog box check Solver Add-In.

- Access to the Solver option is now available from the new menu option Tools | Solver

These websites provide more information on using linear programming in operations:

- Economics Network (

www.economicsnetwork.ac.uk/cheer/ch9_3/ch9_3p07.htm

) provides a detailed explanation and Excel worked example. - IBM (

www-128.ibm.com/developerworks/linux/library/l-glpk1

) has a worked example.

Queuing theory

Agner Krarup Erlang, a Danish engineer who worked for the Copenhagen Telephone Exchange, had the problem of estimating how many circuits were needed to provide an acceptable telephone service. He found out by empirical observation that the relationship between the number of circuits and the number of telephone customers who could be provided with an acceptable level of service was not as obvious as it at first seemed. For example, in his experiments where one circuit was provided on a network, adding just one more could reduce waiting time by over 90 per cent, rather than just halving it as simple logic might suggest. He published the first paper on queuing theory in 1909 and this new operation scheduling technique was born.

Queuing theory can help answer operational questions such as these for a service business such as a restaurant, bank or call centre: Given the present resources:

- How long will a customer have to wait before they are served?

- How long will it take for the service to be completed?

- How big a waiting area will be needed for the queue?

- What is the probability of a customer having to wait longer than a given time interval before they are served â the classic service standard problem calling for, say, âall telephone calls to be answered within 10 rings'?

- What is the average number of people in the queue?

- What is the probability that the queue will exceed a certain length? This can cause congestion, say in a bank or supermarket.

- What time period will the server be fully occupied for and how much idle time are they likely to have, bearing in mind this is a cost to be minimized?

The technique can be used for any operational problem where efficiency is determined by calculating the optimal number of channels required to meet a level of demand. J E Beasley, formerly of the Tanaka Business School (Imperial College) and currently Professor of Operational Research at Brunel University, provides helpful notes on the subject at this web link (

http://people.brunel.ac.uk/~mastjjb/jeb/or/queue.html

).

High inventory levels are popular with marketing departments, as having them makes satisfying customers an easier task; they are less popular with production departments who have to carry inventory costs in their budgets. Finance departments insist on having the lowest possible stock levels, as high stock pushes working capital levels up and return on investment down. (Look back to Financial ratios in

Chapter 1

on accounting to see how this works.) This tussle between departments is a strategic issue that has to be resolved by top management. The birth of Waterstone's, the bookshop business founded by Tim Waterstone, fortuitously a marketing visionary, qualified accountant and the company's managing director, provides an interesting illustration of the dimension of the stock control issue. Until the advent of Waterstone's the convention had been to store books spine out on shelves, in alphabetical order, under major subject headings â Computing, Sport, Travel. This had the added advantage of making it easy to see what books needed reordering and stock counts were a simple process. Waterstone, however, knew that âbrowsers', the majority (60 per cent, according to his research) of people who go into bookshops to look around, had no idea

what book they wanted, so didn't know where to start looking. His differentiating strategy was that as well as following the conventional model of having books on shelves, he scattered the books in piles around the store using a variety of methods: new books in one pile, special offers in another. Sales and profits soared, sufficient to more than compensate for the near doubling of book stock.

Inventory categories

There are three different categories of inventory that a business needs to have and keep track of:

- Finished goods: These are products ready to ship out to customers. For Apple these would be computers, iPods and so forth, for General Motors vehicles and for a baker loaves of bread.

- Work in progress (WIP): These are products in the process of being completed. They have used up some raw materials and had workers paid to start the manufacturing process, so the cost will reflect those inputs. For General Motors WIP would include vehicles awaiting paint or a pre-delivery inspection.

- Raw materials: These are the basic materials from which the end product is made. For General Motors this would include metal and paint, but it could also include a complete bought-in engine for the vehicles in which they use third-party power units.

Economic order quantity (EOQ)

Businesses have to carry a certain minimum amount of stock to ensure that the production pipeline works efficiently and likely demand is met. So the costs associated with ordering large quantities infrequently and so reducing the order cost but increasing the cost of holding stock has to be balanced with placing frequent orders, so pushing the costs in placing orders up, but reducing stock holding costs. EOQ is basically an accounting formula that calculates the point at which the combination of order costs and inventory carrying costs are the least and so arriving at the most cost-effective quantity to order.

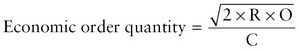

The formula for EOQ is:

Where: R = Annual demand in units; O = Cost of placing an order; C = Cost of carrying a unit of inventory for the year.

InventoryOps.com, a website created and run by Dave Piasecki to support his book

Inventory Accuracy: People, Processes,

&

Technology

(2003, Ops

Publishing), provides a useful starting point in your quest for information on all aspects of inventory management and warehouse operations. At this link (

www.inventoryops.com/economic_order_quantity.htm

), you will find a full explanation of how to use EOQ.

As well as using efficient operation and control procedures an organization has to deliver a quality product or service. Quality in operations does not carry quite the same meaning as it does in, say, marketing, where it signifies something of a high standard. In operations, quality means that something meets a set of prescribed standards and performs as expected. In other words, promises are made and kept. But quality is also part of the efficiency equation too. Quality below standard can lead to high waste, disrupted schedules and lost orders.

Toyota, an early adopter of âLean Manufacturing' and âJust in Time Production', both cost-reduction strategies, hit the buffers in January 2010 when they had to announce a recall of up to 1.8 million cars across Europe, including about 220,000 in the United Kingdom, following an accelerator problem. The company share price sagged by US $25 (£15.9/â¬18) billion when the news broke. Akio Toyoda, the company's president appeared before a US Senate hearing to apologize, where he explained that the company's quality problems had been caused by its growth outstripping the speed with which it could develop the appropriate technical expertise. He went on to say that the company's priorities, traditionally ranked as safety, quality and volume, had become confused, with the last moving to a higher position.

The ideas, concepts and techniques that drive thinking on quality come from these management ideas.

Inspection

Frederick W Taylor (see above) in his book

The Principles of Scientific Management

stated that one of the clearly defined tasks of management was to ensure that no faulty product left the factory or workshop. This led to a focus on the detection of problems in the product, testing every item to ensure that it complied with product specifications. The task was carried out at the end of the production process using specially trained inspectors. The âbig idea' emerging from this approach was defect prevention as the means to ensure quality control. Inspection still plays a part in modern quality practices, but less as an answer and more as one tool in the toolkit.

Philosophy

W Edwards Deming (

www.deming.org

), an American statistician and member of the faculty at the New York University Graduate School of Business and Columbia University, where he taught up until 10 days before his death in 1993, is considered as the founder of modern quality management. He took the inspection aspect of quality control a stage further with the introduction of statistical probability techniques. His view was that quality should be designed into products and processes and that mass inspection was redundant as statistical sampling using control charts will signal when a process is out of control.

Deming is remembered most for his 14-point âSystem of Profound Knowledge'. In this he explains that becoming a quality-driven organization requires everyone, starting with top management, âto fully embrace a new way of thinking that involves seeking the greater good for everyone involved and implementing continuous improvement'. He wanted slogans, targets and numerical targets removed and emphasized to all employees in the company that if change is to be made and processes are to be continuously improved then it's down to them to achieve it. Deming's ideas were adopted enthusiastically by the Japanese whose economy, having been crippled by the war (WW2), was ready to embrace radical change. It was not until the Japanese motor industry was cutting deep into its home market that US industry woke up to Deming's message on quality. Total Quality Management, Quality Circles and Six Sigma have become buzzwords for variations and extensions of Deming and other pioneers' work on quality. The latter term was in use in the 1920s where mathematicians used it as the symbol for a unit of measurement in product quality variation. But it was not until the mid-1980s that engineers in the US company Motorola used âSix Sigma' first as an informal name â later as a brand â for their initiative aimed at reducing defects in production processes. The name Six Sigma was chosen because mathematically it represents 3.4 parts â or defects â per million, an extremely high level of quality.

Information technology is universally seen as important by all major business schools, but taught differently and with a different level of emphasis by all. At London Business School the course is relatively short, entitled âIT for Business Value', and has two intended outputs: to enhance students' confidence in choosing the right technology for meeting business needs; and to examine issues involved in managing the implementation of business systems. At Wharton the Management Information Systems (MIS) course on the MBA programme covers âthe practice of using computer and communication systems to solve problems in organizations and provide the essential skills and

technology-based insights needed in order to manage effective problem solving with information technologies and systems (IT&S), and to extract the most value from an actual or potential information system'. The course itself is organized around several âhands on' cases or projects, through which student teams become familiar with important information technologies, including databases and the internet. MBAs will be expected to have some appreciation of these key issues, though they will usually expect to be able to rely on professional expertise either from within the organization or outside.