Connectome (23 page)

Authors: Sebastian Seung

Â

I have always had a fetish for knives. When I was a Cub Scout I got my first pocketknife, with two cheap blades that quickly tarnished. An older boy showed me his bright red Swiss Army knife bristling with shiny tools as well as blades, and I was overcome with envy. Today I prefer German chef's knives made of carbon stainless steel. (I am not enough of a fanatic to prefer the sharper knives that rust.) I love the whirring sound of knife edge on sharpening steel, and the satisfying feeling of gliding through the flesh of a tomato.

Diamonds, on the other hand, I never understood. Yes, they sparkle, but so does a piece of cubic zirconium or even cut glass. How much more lovely is the pale blue of aquamarine or the blood red of ruby! Surely those beautiful colors are more passionate than the vacuous transparency of diamond.

But then I met the diamond knife.

To understand how special this tool is, let's start with a riddle: What is the difference between a knife and a saw? You might reply that a saw is jagged while a knife edge is smooth, or that a knife is tapered to a sharp edge while the edge of a saw is blunt.

But these distinctions melt away under a microscope. However smooth it may appear to the naked eye, the edge of any metal knife looks blunt and jagged when magnified. Even the finely honed blade of a sushi chef looks as crude as a bludgeon.

But there is one knife whose rarefied perfection holds up to close inspection. The edge of a well-honed diamond knife looks perfectly sharp and smooth, even under an electron microscope. It is just 2 nanometers wide,

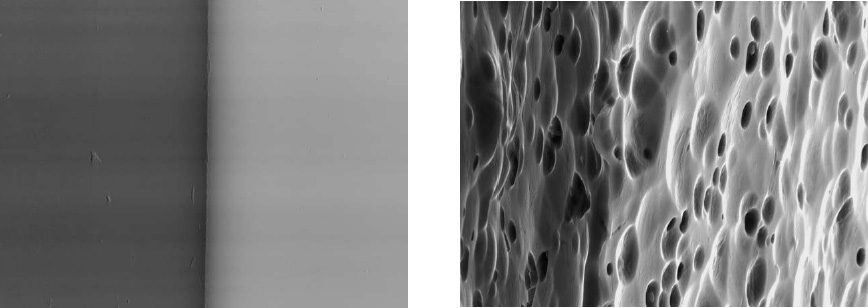

or about 12 carbon atoms. Small nicks on the atomic scale may be visible, but these are rare on a high-quality blade. Its superiority to a metal knife is obvious in the electron microscope images shown in Figure 29.

Â

Â

Â

Â

Figure 29. Knives: diamond

(left)

versus metal

(right)

Â

The diamond knife is the most advanced of the many types of blades used during the centuries-long history of microscopy. The cellular structures of plant and animal tissues are best viewed in specimens prepared by cutting slices, which, for light microscopy, should be as thin as a human hair. At first, specimens were prepared manually using razor blades. In the nineteenth century, inventors developed machines called microtomes. The piece of tissue advanced toward the knife (or vice versa) in small steps, yielding uniformly thin slices.

A microtome can cut as thin as a few micrometers. This was more than sufficient for light microscopy, but the invention of the electron microscope made it necessary to cut even thinner. Keith Porter and Joseph Blum

constructed the first ultramicrotomes in 1953. These machines cut slices that were an astounding 50 nanometers in thickness, more than a thousand times thinner than a human hair. Ultramicrotomes were first fitted with glass knives, but diamond knives proved better. Their perfect sharpness yields clean cuts, and they are durable enough to cut many slices before dulling. As you might imagine, brain tissue has to be prepared very carefully before it's cut in an ultramicrotome. Because of its soft, tofu-like consistency, the tissue would fall apart if it were sliced fresh, so it's embedded in an epoxy resin that hardens into a plastic block.

Ultramicrotomes were first used to obtain single two-dimensional images, like those shown in the figures in this chapter. In the 1960s researchers took the obvious next step of imaging a long series of many slices. This method, known as

serial electron microscopy,

produced a three-dimensional image by stacking up two-dimensional images of many slices. In principle, it's possible to image the entirety of every neuron and synapse in a piece of brain tissue, and perhaps even an entire brain. That's just what we need for finding connectomes. In practice, however, the method is laborious. Because the slices are so fragile, it's not easy to pick them up and place them inside the electron microscope. Every now and then a slice is damaged or lost. There is ample opportunity for error, as even a small piece of brain produces a huge number of thin slices.

For several decades we had no solution to this problem. And then a German physicist had a simple but brilliant idea.

Â

Heidelberg, a lovely German city about an hour's drive from Frankfurt, seems an unlikely incubator for futuristic technologies. A half-ruined castle draws tourists in droves. The old part of town is paved with cobblestones and peppered with bars and restaurants serving raucous students from Ruprechts Karl University. If you're feeling the need to think profound thoughts, head to the Philosopher's Walk, a mountain trail with a splendid view of the Neckar River, where you can channel the spirits of Heidelberg intellectuals like the philosophers Hegel and Hannah Arendt.

Near one of the Neckar's bridges sits a brick building, the Max Planck Institute for Medical Research, at 29 Jahnstrasse. The building appears modest, but it has housed five Nobel laureates in its history. It is one of eighty elite institutes operated by the Max Planck Society, the crown jewel of German science. Each institute is run by several directors, each with a large budget, a small army of research assistants, and a skilled technical staff. The decisions of the Max Planck Society are made by vote of its members, the several hundred directors of the institutes. It is a very exclusive club.

One of the previous directors at 29 Jahnstrasse was Bert Sakmann, who shared the Nobel Prize for his invention of patch clamp recording, now one of the standard tools of the neurophysiologist. He recruited the physicist Winfried Denk to become a new director at the institute.

Denk is a large man, with the commanding physical presence of a German feudal lord. (Maybe that's not surprising; Max Planck directors are about as close as you can get to feudal lords in the modern world.) Denk also impresses with his wit. A science lab is no magnet for comic geniuses, but there are some exceptions. I'll never forget the seminar of a brilliant applied mathematician filled with hilarious riffs on sex, drugs, and rock and roll, which made me laugh so hard that my stomach hurt and tears rolled down my face, obscuring my view of the equations. Denk's one-liners reveal his agile mind, although to get the full effect you must be a night owl, as he prefers the “Dracula schedule” of rising late and working until close to dawn. The experience is well worth it, as the quips and aphorisms flow most freely after midnight.

In the basement of 29 Jahnstrasse, three electron microscopes are protected from temperature fluctuations by special enclosures. Pumps evacuate their metal chambers so that electrons may fly freely inside without colliding with air molecules. The microscopes are a bit finickyâat any given time, one might be in need of repair. But the others image brain tissue continuously for weeks or months.

When Denk first arrived in Heidelberg, he was already world famous as one of the inventors of the two-photon microscope. (I mentioned earlier that this tool was used to see creation and elimination of synapses in living brains of animals.) After shaking up light microscopy, he decided to automate serial electron microscopy. His idea was simple: repeatedly image the face of the specimen exposed by cutting, rather than image the slices.

In 2004 Denk unveiled his invention, an automated system consisting of an ultramicrotome mounted inside

the vacuum chamber of an electron microscope. He called his method SBFSEM, short for “serial block face scanning electron microscopy.”

By bouncing electrons off a block of brain tissue, it's possible to acquire a 2D image of the block face. Then the blade of the ultramicrotome scrapes a thin slice off the block, exposing a new face, which is imaged again. This process is repeated to acquire a stack of 2D images similar to those produced by conventional serial electron microscopy.

Why is it better to image the block face rather than the slices? Because the block is sturdy while the slices are fragile. Even if slices are not lost through mishandling, each ends up slightly deformed in a different way. Stacking up the images of the slices produces a corrupted 3D image. In contrast, images of the block face contain little or no distortion because the sturdy block deforms so little.

Imaging the block face allowed the ultramicrotome to be placed inside the electron microscope, creating an automated system that integrated both cutting and imaging. This improved reliability by eliminating the error-prone manual transfer of slices from ultramicrotome to microscope. The slices were as thin as 25 nanometers,

half the 50 nanometers feasible with manual cutting and collection.

Like mountain climbers, scientists strive to be first. Glory goes to discoverers, not followers. But science also resembles investingâyou can be too early rather than too late. In his 2004 paper Denk acknowledged an earlier inventor named Stephen Leighton, who had developed a similar idea in 1981. Leighton's invention was too early to be practical, as it would have produced more data than anyone could handle at the time. By the time Denk came up with the idea independently, computers had advanced enough to store the large amounts of data.

How do you know when an idea's time has really come? As with investments, it often becomes obvious only in retrospect, when less upside remains. Simultaneous invention by two people is one sign, but even more telling is invention of two different solutions to the same problem. As it happens, Denk's work was paralleled by another effort to automate the process of seeing smaller.

Â

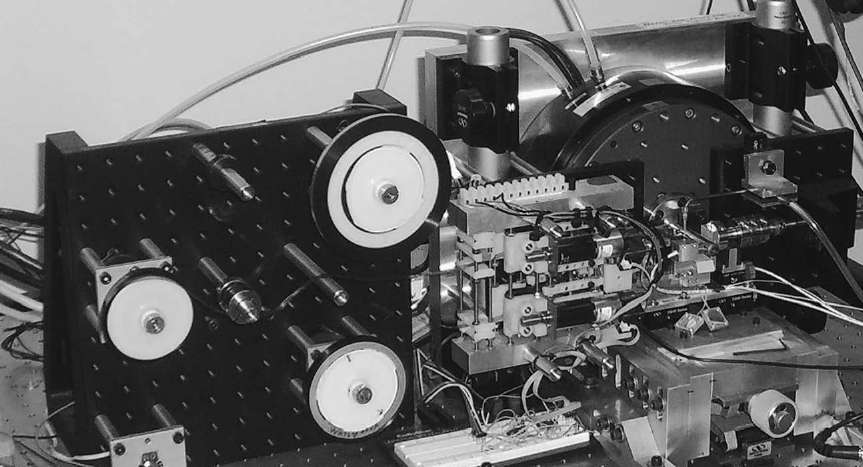

No ivy grows on the Northwest Building at Harvard University. The smooth glass exterior exudes no hint of history, which is appropriate for a building that houses the cutting edge of scientific research at Harvard. Enter the expansive lobby and wander down to a basement room. Before your eyes is a bewildering machineâa complex, Rube Goldberg contraption (see Figure 30). It's not clear what to look at, until the slow motions of a tiny plastic block catch your eye. Its transparency emits a hint of orange and envelops a black fleck, a stained piece of mouse brain.

Â

Â

Â

Â

Figure 30. The Harvard ultramicrotome

Â

Some other parts rotate lazily. Plastic tape is rolling off one reel and collecting on another, in the style of a 1970s reel-to-reel tape recorder. You spy yet another reel lying on the table beside the machine. Unrolling some tape, you hold it up to the light to see brain slices spaced at regular intervals along its length. Finally you realize that the function of the machine is to transform a piece of brain into something like a film strip, by cutting and collecting slice after slice on the tape.

Cutting slices is challenging enough; the problem of collecting them is even worse. As any amateur chef knows, thin slices often stick to the knife instead of falling onto the cutting board in an orderly way. The conventional ultramicrotome solves this problem using a water trough. The knife is mounted on one of the edges of the trough, so that the cut slices spread out nicely onto the surface of the water inside. The operator then plucks the slices out of the water one by one and takes them to the electron microscope for imaging. Mishandling during this process can result in annoying folds or in loss of entire slices.

The ultramicrotome at Harvard, like the conventional ones, uses a water trough to pull the ribbon of brain slices off the knife. The new element in the Harvard apparatus is a plastic tape, which ascends from the water's surface like a conveyor belt. (See the bottom of the image shown in Figure 31 for the plastic tape. You may be able to make out two slices of mouse brain touching end to end in the vertical ribbon centered above the tape.) Each slice sticks to the moving tape and is carried up out of the water into air, where it dries rapidly. The end result is a set of fragile slices stuck onto a much thicker and stronger tape that's collected on a reel. The important feature is that there's no possibility of human error, since the operator never needs to handle a slice manually. And the plastic tape is robustâvirtually indestructible.

Â