The Big Ratchet: How Humanity Thrives in the Face of Natural Crisis (17 page)

Read The Big Ratchet: How Humanity Thrives in the Face of Natural Crisis Online

Authors: Ruth DeFries

The power to smash open the bottleneck for soil fertility was game-changing, but that was not the only, or possibly even the main, impetus for the industrialization of nitrogen fixation. The other was gunpowder. Chilean saltpeter was one source, but supplies were dwindling and largely in the hands of British companies. With the 1914 outbreak of World War I, Germany’s motivation for synthesizing large amounts of nitrogen switched from producing grain to producing implements of war. Germany had lost its access to the British-controlled Chilean source. With little domestic supply to produce munitions, BASF ramped up the Haber-Bosch process.

After the war, the British victors inspected German factories, hoping to learn how the enemy had managed to produce so many explosives. But the British could not replicate the process, until they found a few German engineers willing to sell their secrets, at a price. The Haber-Bosch process spread to Britain and soon became its main source of fixed nitrogen. Industrial espionage joined trade, conquest, and the spread of ideas from one farmer to another in the roster of how humanity accumulated knowledge to resolve the conundrums of settled life. That spelled the end of the Chilean nitrate trade and the beginning of the proliferation of the Haber-Bosch process

across the industrialized world.

Oh, the paradox of Haber’s life. On one side, his invention fueled explosives for world wars and conflicts that have killed millions. On the other, he solved the problem that for many thousands of years had caused farmers to bemoan the loss of soil fertility with each harvest.

Billions of people have been fed because of Haber’s invention, but millions have died, too. Such a grand contribution to science and humanity had such mixed results. The contradiction of Haber’s life grows even greater in light of his other works. Haber contributed to Germany’s war effort not just through ammonia to make munitions. He also turned his genius to producing mustard gas and other poisonous substances. He justified the pursuit as humane, claiming it would shorten the war. His wife, Clara, also a chemist, could not bear the thought and committed suicide. Many considered Haber a war criminal.

When the Nazis came to power, they allowed Haber to retain his post as director of the famed Kaiser Wilhelm Institute for Physical Chemistry despite his Jewish heritage. Haber’s Jewish colleagues received no such exception. When the Nazis ordered Haber to dismiss his colleagues, he refused. Instead, on April 30, 1933, he submitted his resignation to the Prussian Ministry of Education. Haber lost his pension and prestige as one of Germany’s great scientists. The United States denied his request to emigrate from Germany, as the quota was already filled for immigrants with distinguished records in science. Haber’s health failed, and he died a broken man in Basel, Switzerland, in 1934 at

the age of sixty-five.

Despite his tragic end, Haber’s invention to industrially fix nitrogen pivoted humanity into a new era in the twentieth century. With no limits on abundant nitrogen gas in the air, humanity’s struggle for fixed nitrogen escaped its reliance on clover, excrement, and microbes, although it took another war before the power of the Haber-Bosch process for peaceful use was fully realized. The Haber-Bosch process had reached the United States by the beginning of World War II. American factories used it to produce munitions. At the end of the war, the machinery and know-how to make explosives remained in place, but the demand was gone. The US government, seeking new uses for munitions factories, like the one at Muscle Shoals, Alabama, supported scientists in agricultural

colleges, hoping to improve and spread the use of nitrogen fertilizers. The Haber-Bosch process became a mainstay of American agriculture after World War II. Production of nitrogen fertilizers, whether from repurposed, war-era factories or new ones built for the purpose, mushroomed more than eightfold in the

second half of the century.

The total amount of food produced in the industrialized world skyrocketed with the invention. But that’s not all: Haber-Bosch also transformed what people ate. More grain meant more animals at the trough, which meant more people enjoying meat, eggs, and dairy more often. Four out of ten people alive at the beginning of the third millennium were subsisting on foods that farmers would not have been able to produce without fertilizer made with the Haber-Bosch process, including grains to feed meat- and

dairy-producing animals. There is no mistaking that the Haber-Bosch process was one of humanity’s all-time pivot points, changing diets and ratcheting up the number of mouths that the world’s supply of food could feed.

The Haber-Bosch pivot ratcheted up the success of our species, but the success is tragically uneven. The success has not brought much hope for the starving child, for millions of farmers, and for many countries that are still struggling to break free from poverty traps imposed in part by degraded soil fertility. One only needs to look at a typical farmer in an African country south of the Sahara desert to see the tragedy. Infertile soils, leached of nutrients from centuries of taking more out with each crop than could be replaced, means low yields, poor diets, and families trapped in an everyday existence of scraping together enough food. A few pennies worth of industrially fixed nitrogen would make all the difference, but many farmers cannot afford even that. This is the bifurcated, lopsided world of today—an excess of fixed nitrogen for the prosperous and a tragic paucity for the poor.

Today, the industrial process fixes more nitrogen from the air than the natural processes of soil microbes and lightning could ever accomplish.

In essence, Haber opened the faucet for nitrogen to flow from the air to the living world. But that same faucet did not flow for phosphorus, the other critically important nutrient, which cycles in nature at only a creeping, geologic-scale pace.

Buffalo Bones and Buried Coral

Farmyard manure, night-soil, ashes, and South American bird guano—rich in both nitrogen and phosphorus—solved the soil-fertility conundrum by nourishing soils with both nutrients in one stroke. As guano grew scarce and the chemists figured out how to fix nitrogen from the air, the single solution for both nutrients came undone. Each nutrient needed its own solution. What’s more, the more nitrogen there is in soil, the more it needs phosphorus.

Some efforts to produce phosphorus for fertilizer were already underway, thanks to Justus von Liebig’s erroneous notion that phosphorus, rather than nitrogen, most often limited crop yields. An industry to sell phosphorus-rich fertilizers to farmers had developed early in the nineteenth century based on bones. As far back as ancient China, people had known that bones could fertilize their fields. In the early years of the nineteenth century, as England was industrializing and the demand for food was rising, an industry took root to steam bones, then crush them with machines into fragments and powder. Demand was so high for the bone meal that England started to import bones from butcher shops in mainland Europe.

Liebig and others before him knew that acid could dissolve the phosphorus in bones to make fertilizer. He gave the recipe in his 1840 book: “The most easy and practical mode of effecting this division is to pour over the bones, in a state of fine powder, half of their weight of sulfuric acid, diluted with three or four parts of water; and after they have been digested for some time to add 100 parts of water, and sprinkle

this mixture over the

field before the plough.” Sir John Lawes, whose experiments had played a large role in confirming the mineral theory, had come to a similar conclusion from his work at Rothamsted Experimental Station. Apparently unaware of Liebig’s published conclusion, Lawes applied for a patent in 1840 to make “superphosphate”—a new fertilizer—from bones or from apatite or other rocks treated with sulfuric acid. Lawes subsequently amended his patent to cover only fertilizer made from rock to avoid perceptions of pilfering on Liebig’s intellectual property, and later accused Liebig of infringement. Lawes himself might have gotten the idea to use rocks to make fertilizer from Sir James Murray of Dublin, who had taken out a patent a few weeks before Lawes. Lawes later

purchased Murray’s patent.

Whoever’s idea it had been, the patent was now in Lawes’s name. An advertisement ran in the

Gardener’s Chronicle

on July 1, 1843: “J. B. Lawes’s patent manures, composed of Super Phosphate of Lime, Phosphate of Ammonia, Silicate of Potass, &c., are now for sale at his Factory, Deptford-Creek, London, price

4s. 6d. per bushel.” The venture met with success. By 1853, fourteen firms in England, one in Austria, and three in the United States

were manufacturing superphosphate. The highly profitable business funded Lawes’s Rothamsted farm.

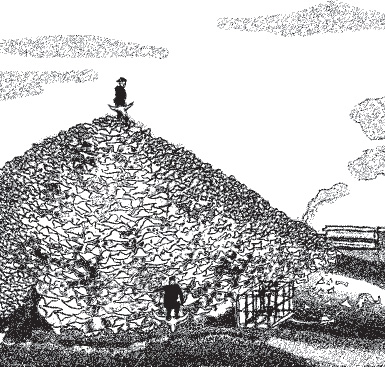

In North America, buffalo skulls and bones scattered across the Great Plains supplied the raw material for the superphosphate factories. Remnants from the slaughter of the great buffalo herds as settlers expanded westward created another industry, as bone-pickers scoured the plains for buffalo remains to send back east. They sold the bones by the wagonload at train depots for a

couple of dollars per ton.

Bones were still in high demand to make superphosphate into the later decades of the nineteenth century. Liebig even accused England of snatching bones from battlefields. He tormented England with the satirical suggestion that it was “robbing all other countries of their fertility. In her eagerness for bones, she had turned up the battle fields

of Leipzig, Waterloo, and the Crimea. She annually removed from the shores of other countries to her own the manurial equivalent of three millions and a half of men.” And “like a vampire,” he said, “she sucks the heart blood from nations without a

thought of justice to them.”

Liebig had reason to be bitter. Lawes was a shrewder businessman. Liebig had been at work on a new phosphorus fertilizer, and James Sheridan Muspratt, the son of a close friend from Britain, had taken out a patent for it in the United Kingdom on Liebig’s behalf. The fertilizer was a mixture of plant ashes, gypsum, crushed bones, and some other minerals fused into pellets in a furnace. Liebig surmised that the ingredients would slowly diffuse into the soil rather than dissolve too quickly and get washed away with the rain. Liebig did not test the mixture in

the field, a big mistake. With the product’s launch in the fall of 1845, British farmers enthusiastically bought the new fertilizer. Much to their surprise, the fertilizer remained on the surface unless they went to the further expense of plowing it under. What Liebig thought would be a better, slowly dissolving fertilizer turned out to be a worse, insoluble one. Liebig’s fertilizer venture was a financial disaster. It tarnished his reputation and nearly cost him his friendship

with Muspratt’s father. Lawes’s formula won the day.

Whether the bones for superphosphate came from butcher shops or buffalo, over time the supply couldn’t keep pace with demand. Prices climbed. The cost of guano was high as well. Some less-than-scrupulous merchants were willing to extract high prices from farmers for fertilizers adulterated with sand, pulverized bricks, and burnt ore. It was no secret that the right rocks could supply the source to make superphosphate. The question was where to find them.

In 1843, the Royal Agricultural Society of England had commissioned a professor and a naval captain to follow a lead about seams in the rocks six days’ journey by bullock cart from Seville, Spain. When they brought back samples from the seams, indeed the fossils were full of

bone fragments and teeth. Then others found similar geologic deposits near Cambridge, Suffolk, and Bedfordshire and in France, Germany, and Belgium. These rocks began to overtake bones as the main

stock for the superphosphate factories. By the late 1860s, the phosphate-rich, geological quirk of Bone Valley, Florida, had been found.

The seemingly limitless supply triggered a

speculative land rush. At the heart of the rush were the remnants of fluke geologic coincidence. Millions of years ago, nutrient-rich water welled up from the deep ocean and nourished an abundance of marine life in the shallow ocean overlying the land that is now Florida. Phosphorus in dead corals, shells, sharks’ teeth, and skeletons dissolved in the water, solidified, and

built up on the ocean’s floor. The result is mile upon mile

of phosphate-rich sedimentary rock just below the surface. The riches of Florida prompted hunts for similar geology elsewhere, which led to the eventual discovery of similarly endowed geologic formations in an eclectic list of countries scattered around the world, including China, Morocco, the United States, South Africa, and Jordan. The abundant fossil phosphorus was the inexpensive, commercially feasible solution that the Royal Agricultural Society was after. Just as Haber-Bosch had replaced the saltpeter trade, so phosphate rocks replaced bone.

By the beginning of the twentieth century, human ingenuity had essentially dismantled the natural phosphorus cycle. Phosphorus in ancient rocks was replacing the nutrients lost with each harvest, while modern sewage systems in industrialized parts of the world were transporting those same nutrients in human waste to rivers and oceans. The short circuit in the phosphorus cycle was not lost on the thinkers of the times. Lord Edward, the amateur biologist in Aldous Huxley’s 1928 novel

Point Counter Point

, echoed the nineteenth-century sentiments of William Shaw, Victor Hugo, and Karl Marx: “You’re simply draining the soil of phosphorus. . . . Pouring it into the sea. And you call that progress. Your modern sewage systems! . . . You ought to be putting it back where it came from.

On the land.”