Moon Lander: How We Developed the Apollo Lunar Module (24 page)

Read Moon Lander: How We Developed the Apollo Lunar Module Online

Authors: Thomas J. Kelly

Tags: #Science, #Physics, #Astrophysics, #Technology & Engineering, #History

SWIP was painful and expensive. Besides the great disruption it caused to our schedules and manufacturing buildup, it forced us in Engineering to approve designs and processes that we had concerns about. I felt torn between two opposing interests: the need to reduce weight versus the importance of safety, reliability, and maintainability. I never compromised on safety, and

rarely compromised on reliability, but I frequently took chances on reduced maintainability, which would come back to haunt me during the two long years of ground assembly, test, and checkout that the flight LMs endured.

Probably the worst choice I made from a maintainability standpoint was the use of fine 26-gauge wire and miniature connectors on signal circuits, which carried voltage but essentially no current. LM had many miles of such wiring, so this one item saved hundreds of pounds—but at the cost of recurring wire breakage and difficulty of mating and demating electrical connectors in the spacecraft. Upgrading to a higher strength copper alloy for the later vehicles (LM-4 and subsequent) helped alleviate the breakage problem.

Grumman’s Manufacturing Department had become expert in chemically milling aluminum alloy and other metals, and we applied this process liberally to structural sheet metal and machined fittings. With chem milling we could create pockets and shapes that were impractical to obtain by conventional machining, and engineers were able to optimize their designs so there was almost no excess metal remaining except that required along the load paths. We obtained major weight savings from this technique. Unfortunately we later found out that chem milling rendered some alloys and part shapes more susceptible to stress corrosion. This occurred when the parts were assembled with less than precise fit-ups into the mating structure, which locked in stresses when the fasteners were tightened, and were exposed to a humid, salty environment, which was standard both on Long Island and at Kennedy Space Center. Months after the first chem-milled parts were installed we encountered cracks, and many inspections and reworks resulted at Bethpage and Cape Kennedy.

With supercritical helium the penalty was system complexity, both onboard and in the GSE, plus a total lack of operational experience by NASA, the military, and the equipment suppliers with such a system. Supercritical helium had to be kept just a few degrees above absolute zero (–459 Fahrenheit), requiring the best available insulation and vacuum technology and extreme care in the fabrication of all components of the system. On Apollo 9’s launch we found out just how tricky this could be.

There were many other changes, some of which caused concern, if not actual problems. We made more extensive use of titanium instead of steel in applications where this would save weight. Titanium was harder to shape and machine and more expensive. It was also in short supply, and even with the Apollo program’s high priority we encountered some delays with large titanium forgings.

We chem milled the skin of the crew compartment down to exactly the thickness needed to meet the structural safety factor criteria and no more. This yielded a thickness of .012 inch (twelve-thousandths of an inch) for the cylindrical aluminum alloy wall of the crew cabin, or about as thick as three

sheets of household aluminum foil. The wall could easily be damaged by a dropped tool or heavy foot, and was therefore covered with protective hard plastic liners throughout its long period of assembly, test, and checkout at Bethpage and Kennedy.

In addition to the big-ticket weight-reduction items, weight was saved by detailed scrutiny of every system and design in the LM. Some of the weight came out in ounces, but it added up to worthwhile amounts. Substantial weight was saved by redesign of the micrometeorite shielding and thermal blankets that covered the external surfaces of LM. We made a very efficient and lightweight combination consisting of fiberglass plastic standoffs bonded to the underlying structure, supporting a .005” aluminum alloy sheet of micrometeorite shield, and insulation blankets consisting of multiple layers of aluminized mylar only one-eighth of a mil (.000125 inch) thick. The mylar blanket material was specially developed for this application.

In the electronics area, emphasis was given to lightweight packaging to save weight. Wire wrap terminals within the electronic boxes were used to increase reliability and reduce weight by minimizing the number of internal friction connectors. Short, direct conductive heat transfer paths, from the heat dissipating components on the printed circuit cards to the attachment flanges of the electronic boxes, were used to enhance thermal control and reduce packaging weight.

In the fluid systems, weight and complexity were minimized by using pressurized propellant or fluid feed wherever possible, with relatively low pressure levels, small pressure drops, and small forces. The requirements for system safety and reliability were paramount, but the weight considerations affected the details of the design. The propulsion and reaction control systems had propellant and pressurant tanks of lightweight titanium, and stainless steel interconnecting plumbing lines that were joined by high temperature brazing.

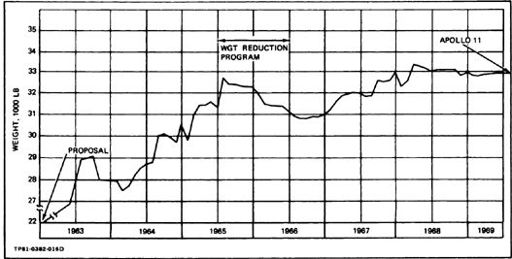

All this painstaking effort paid off handsomely. The growth of LM weight was abruptly arrested in mid-1965, and a reduction of more than twenty-five hundred pounds was achieved. Reductions continued throughout 1966 until actual weights began to dominate and the changes resulting from the LM critical design review in March 1966 were felt, showing further increases. A similar weight-reduction effort on a smaller scale was conducted late in 1967 and provided an acceptable margin below the spacecraft control weight. For the later missions (Apollos 15–17, LMs 10–12) increased Saturn 5 capability permitted an increase in LM weight at Earth launch to thirty-six thousand pounds. The four-thousand-pound growth was used to provide an extended lunar stay time of three days and to carry the lunar roving vehicle, a collapsible, electric-powered car for traversing the Moon’s surface, and additional scientific equipment and sample return capability.

Participation in the LM SWIP effort was very widespread in Engineering and Manufacturing and throughout our major subcontractors. The difficult work of devising and searching out possible weight-reduction candidates was spearheaded by Tobin and Wiedenhaefer and the SWIP team. Their persistence and drive inspired us all and was reinforced by LM Engineering management, especially Carbee, Whitaker, and their section heads. The whole exercise also benefited greatly from the steady support and guidance provided by NASA’s Bill Lee, Owen Maynard, and Caldwell Johnson. They were firm in demanding results but optimistic about the outcome.

The lunar module’s weight history from proposal to Apollo 11. (Courtesy Thomas J. Kelly) (

Illustration credit 8.1

)

I was very upset at having to tear apart the LM design as it was nearing completion because I also felt the intense schedule pressure from NASA and Grumman management. Phase-in of changes provided a practical relief valve to the schedule impact problem. In the beginning I also wondered if we could achieve our weight-reduction goals, but the supreme confidence shown by our SWIP team and their NASA counterparts overcame my doubts. Within Grumman it was a great team effort; all elements of the program contributed where they could. Manufacturing suggestions often resulted in process improvements or design simplifications that saved weight. In engineering, the design and materials groups were particularly important. Some new materials, like the ultra-thin aluminized mylar insulation, were created in response to industry stimulus by our Engineering Materials Group.

Near the end of 1966 SWIP activities took up less of my time as the effort successfully wound down. By then a new round of problems and priorities had arisen to claim my attention and LM weight was a less urgent concern. I

felt quiet satisfaction with the results of SWIP, even though we could not claim any particular credit for it as we were just fixing the weight growth problems that we ourselves had generated. Grumman rose to the challenge, however, and provided the techniques, leadership, and skilled people who solved the problem within the cost and time constraints of the program. We could not have done otherwise.

9

Problems, Problems!

As the LM moved from paper design to hardware from mid-1966 to the flight missions in 1969, the work of Engineering gradually shifted from design to trouble shooting and problem solving. The philosophy of the Apollo Project was to obtain reliability by tracking down the root cause of every test failure and correcting it. This idea was reinforced at Grumman, where we persistently examined the data, analyzed, and retested until we found the reason for each test failure. As more LM components and assemblies were tested, more failures occurred, and we found ourselves tracking hundreds of failures that could not be closed until we had found the cause and implemented corrective action.

The failures were recorded by Quality Control, which witnessed all tests, and dispositioned by the Reliability Section in Engineering. Many different groups within Grumman were often involved in analysis, retesting, and devising appropriate corrective actions. George Weisinger, head of LM Reliability, led the failure tracking and closeout activities. A thin, wiry fellow who seemed to be constantly in motion, Weisinger knew where to look for likely causes of failures and whom to enlist in finding a solution. At the peak of the failure reporting and corrective action effort in 1968, we averaged three hundred open LM failure items “on the books” and had several hundred engineers at Grumman and our subcontractors engaged in closing them out. Each failure was followed through the closeout process to assure that none were “lost in the shuffle.”

Most of the failures were tracked down and resolved promptly—within a few weeks and without major cost or schedule impact. A few were chronic, recurring problems that required technical detective work to find the underlying cause and design ingenuity to devise an effective solution. Every LM subsystem had major development problems, so the severity of the problems was a matter of degree and depended upon the point in the LM program at

which the problem arose. Problems that emerged later in the program, closer to flight launches, were more difficult to handle without major impact to the program schedule.

In this chapter I recount some of the more memorable technical problems, chosen because of either their impact on the program or the extent of my personal involvement in their solution. This is only a small sample; for LM to reach the Moon and return,

all

problems had to be closed out prior to launch from KSC.

Propulsion and Reaction Control System Leaks

Leaks in these critical systems were a chronic problem from the completion of the first heavyweight propulsion test rigs (HA-1 and HD-1) in mid-1964 through the manufacture of the flight LMs. Leaks occurred on both the pressurant (helium gas) and the propellant fuel and oxidizer sides of the system. The rocket fuel was called 50/50 (50 percent hydrazine, 50 percent unsymmetrical dimethyl hydrazine, or UDMH), and nitrogen tetroxide (N

2

O

4

) was the oxidizer. Although no leaks were tolerable anywhere in the systems, propellant leaks were extremely serious because the propellants were highly toxic volatile liquids, and being hypergolic, their fumes would ignite if combined. The search for leak-tight joint designs was long and arduous on LM, and improvements were still being made well into the flight program.

I was concerned about leakage in LM’s fluid systems even before we prepared our proposal. Without working out the details at that time, we proposed using welded or brazed joints to eliminate mechanical connections in fluid systems and mechanical energy absorbers in the landing gear to eliminate the potential leakage of hydraulic shock absorbers. As the LM design took shape in 1963 and 1964 we chose stainless steel tubing joined by high-temperature nickel-silver brazing for the propulsion and RCS systems to minimize the number of mechanical joints. Threaded or bolted mechanical joints with gaskets or O-ring seals were allowed for replaceable components, such as tanks, valves, filters, and regulators.

This design policy looked good on paper, but as soon as we gained experience with real system components and plumbing in the cold flow facility at Bethpage, where we pressurized and flowed the systems with inert fluids, and the “live” propellants and hot firing facility at White Sands, it was revealed as inadequate. None of our mechanical joint designs were leak-tight and even the brazed joints leaked unless they were perfect, with full, even flow of the brazing material over the contact area of the joint.

We detected leaks by pressurizing the system with air or nitrogen containing a small fraction of helium and using a sensitive helium detector (“sniffer”), a portable mass spectrometer set to detect a single element, helium. The sensitivity

of the sniffer could be adjusted from one to fifty parts per million; the pass/fail setting was two parts per million. When helium exceeding the detection threshold was encountered the sniffer sounded an audible alarm horn, which blew louder the more helium present. The first time we checked the heavyweight rigs for leaks at low pressure on the factory floor it sounded like an air raid was in progress, with sirens wailing everywhere. For a while we blamed the sniffers (too sensitive!), but we found that many of the suspect joints would also show leaks in the common, low-tech bubble test with detergent solution. We stopped the leaks on the heavyweight rigs at Bethpage by replacing gaskets and O-rings and tightening bolts and threaded fasteners to their allowable torque limits.