SAS Urban Survival Handbook (31 page)

Read SAS Urban Survival Handbook Online

Authors: John Wiseman

Tags: #Health & Fitness, #Reference, #Survival, #Fiction, #Safety, #Self-Help, #Personal & Practical Guides, #General, #Survival Skills

Don’t use a belt sander if you want a ‘perfect finish’—they are specifically for removing large amounts of material. The belt may wander on the rollers. If worn too thin, or snagged on a nail, the belt may shred and foul the machine. A fitted dust-collection apparatus is essential—as are safety glasses and good breathing protection.

WARNING

If you plug in a belt sander and it is switched on, it will ‘run away’. Never put it down or abandon it until the belt has totally stopped moving.

Orbital sanders

Also called finishing sanders, the flat sanding pad moves in small circles—it does not rotate. The work is done by using various grades of sandpaper—coarse for heavy smoothing, fine for light finishing—NOT by exerting downward pressure on the tool. This will not make the sander more efficient, it will tear the paper, cause a lot of vibration and possibly overheat the motor. Orbital sanders can produce a better finish than belt sanders. A fitted dust/debris collector is ESSENTIAL—as are safety glasses and adequate breathing protection.

WARNING

Fitting new sanding papers can be very fiddly—NEVER do so when the machine is plugged in or switched on.

SANDER PROBLEMS

Mechanical sanders never quite get ‘into’ corners—and don’t produce perfect results without a lot of time and patience. Flexes tend to be short. Assess whether this will be a problem before you start and use an extension lead (fully unwound) if necessary. If you work at the top of a ladder, the extension socket may swing about in mid-air. Avoid this!

If you never intend to tackle large sanding jobs, consider using ordinary sandpaper (or, in some cases, steel wool) instead. If you only want to sand paintwork for repainting, sugar soap, strong detergent or ‘liquid sander’ (all used with care) could be a lot easier. Most sanders will not cope with curved surfaces and wooden mouldings.

SAWS

Jigsaws

Jigsaws cause a lot of vibration. The blade, which is exposed, moves up and down rapidly and—because most cut on the upstroke—throws up a lot of debris. Some blow the dust away in front of themselves, so that you can see the cut line. You will find yourself leaning over and peering closely, especially on finer work—and getting a faceful. You MUST wear eye and breathing protection.

NEVER put your hand or any other part of your body underneath the workpiece. The blade protrudes and could easily slice a finger at high speed.

There should be no need to exert much pressure—let the blade do the work. Gently guiding the saw should be enough, unless the blade is blunt or unsuited to the type/thickness of material you are trying to cut. When you push, the blade twists or moves out of alignment, so the cut line wanders and you risk breaking the blade. Jigsaws require a lot of concentration to follow a line accurately—especially at speed. Buy one with variable speeds. You should work more slowly with plastics. Cutting metal requires the use of a lubricant.

REMEMBER

If the jigsaw has an adjustable sole plate for angled cutting—take care. Always make sure the sole plate is well tightened in position. Don’t work too quickly—it’s harder to control an angled cut. Let the blade stop moving before you put the jigsaw down.

Only use the ‘lock-on’ button if you really must—otherwise, if you have an accident, the saw will carry on working by itself.

Some jigsaws allow guides to be fitted, which enable you to follow the edge of a workpiece. These can help you control the tool. Never overreach, but travel with the saw if you can.

Blades

Blades must be chosen with care. You will find many kinds available. They vary greatly for hard and softwoods, plywoods, coarse or fine work, metal, plastic, straight or curved cutting. Replace blades when they become worn—that means as soon as they demand more pressure to do the job. A lot of heat is generated by friction and sawdust may smoulder or ignite. Unplug the tool BEFORE attempting to replace blades. A screwdriver/ Allen key is usually required to do the job. Make sure the new blade is well fixed in.

Circular saw/power saw

Circular saws (also called power saws) are a lot more dangerous than jigsaws. Cutting is done, as the name suggests, by a circular blade. Much care and concentration are required to maintain and use a circular saw.

Circular saws cut on the up stroke and guards should ALWAYS be fitted.

NEVER

operate a circular saw without a bladeguard AND another guard which swings back as the cut is made (and moves back at the end of the cut).

NEVER

fix any guard in any position to ‘get it out of the way’.

NEVER

put your hand or any other part of your body underneath the workpiece. The blade penetrates and could easily cut off your hand. Always wear eye and breathing protection.

There is a variety of different blades available, for different jobs. Don’t push the saw through the workpiece. If you feel you have to, the blade may be blunt or incorrect for the material you are trying to cut. The blades must be sharpened by a professional.

Make sure the blade is well fixed. Let it reach full speed before starting to cut—and let it stop before lifting the saw away from the workpiece.

NEVER NEVER NEVER touch the blade, or attempt to replace it, while the tool is plugged in. There should not be a lock-on button—if there is, do NOT use it. NEVER. If an accident occurs, a runaway circular saw could do a lot of damage. If faced with a choice when buying, a lock-OFF button is by far the safer option.

If you are left-handed, you may find using a circular saw difficult. With most models, it is hard to see the cutting line.

REMEMBER

With jigsaws and circular saws, it is easier to cut large sheet materials if you drape the flex over your shoulder.

OTHER OPTIONS

Power planers

Use with great care. These machines eat wood! They also spew out a great quantity of debris. Always wear eye and breathing protection. Always try to arrange debris collection at source with a collection bag, or vacuum cleaner attachment.

- ◑ Make sure

NOT

to connect the power while the tool is switched on. - ◑ NEVER leave the tool resting in an upright position, resting on the blade. If it starts up, it may run away, possibly causing a serious accident.

- ◑ NEVER switch on until in position to commence planing.

- ◑ NEVER put the tool down until the blades have finished rotating completely.

- ◑ NEVER rest the tool on the palm of your hand, or on your lap—this is an invitation to disaster.

- ◑ NEVER plane a piece of hand-held wood!

- ◑ ALWAYS clamp the workpiece, or use a vice.

- ◑ ALWAYS work on a clear firm surface.

The cylinder of blades can usually be sharpened, but may need to be replaced in some models. Don’t expect to be able to plane nail and screw heads.

NEVER NEVER NEVER touch or attempt to replace a blade while the tool is plugged in. The blade (in domestic models) revolves at up to 20,000 revolutions per minute—more than enough to inflict serious damage.

Electric screwdrivers

Rechargeable, battery-operated and conventional versions are available. They are NOT magic screwdrivers, and all the safety rules for screwdrivers apply—as do power-tool safety rules, in mains-operated versions. You are unlikely to have all the tip styles to suit all screw sizes and types.

The turning force (torque) varies from model to model—but, unless you observe all the normal rules (drilling pilot holes, for example), you might find that the electric screwdriver wants to turn in your hands while the screw stands still!

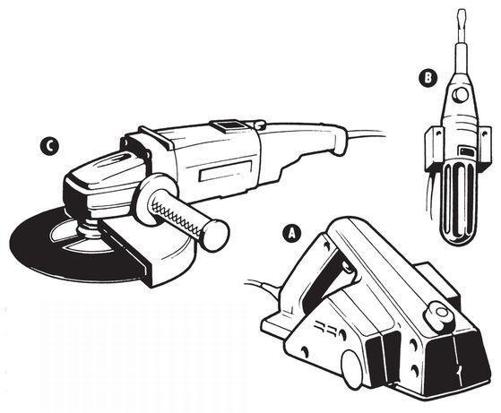

Power planers (A) need careful adjustment. Electrical screwdrivers (B) are only ‘magic’ if you have drilled pilot holes. Angle grinders (C) have many uses, but the larger ones tend to be unwidely.

NEVER work ‘into’ your hand, but always on a firm surface. Don’t work on your lap. Keep all parts of your body out of the way, in case you slip.

Angle grinders

These are the most recent tools to creep into the domestic market. Ranging from small specialist tools to large unwieldy professional (or hire shop) models—they basically consist of a power tool which turns a circular grindstone at great speed.

Angle grinders create an enormous amount of debris and dust—guards should be fitted. Eye and breathing protection is essential. Damp down the area which is to be worked—observing ALL the rules of electrical safety!

The basic function of an angle grinder (depending on size and power) is to grind away material. They may be used, for instance, for cutting through plaster on walls, when ‘letting in’ a new fireplace; for cutting paving slabs; for slicing through brick walls.

Larger models may have an almost ‘gyroscopic effect (have you ever noticed the tendency of toy gyroscopes to find their own orientation when turning quickly?) and may be hard to control. Get your balance! Be very careful if using up a ladder. Don’t overreach.

Keep all parts of your body out of the way. Angle grinders are very dangerous and messy. They require a lot of concentration and, sometimes, a lot of strength. Bad accidents on record make ‘gory’ reading.

WOOD DUST

This is VITAL information for anyone who works with wood. Wood dusts, surprisingly, pose severe hazards. They can cause, depending on the type of wood, amount of exposure and the

This is VITAL information for anyone who works with wood. Wood dusts, surprisingly, pose severe hazards. They can cause, depending on the type of wood, amount of exposure and the

sensitivity of the individual: dermatitis, asthma, bronchitis, chronic lung diseases, lung fibrosis, eye irritation, nasal and sinus irritation, and they have been linked with cancer.