SAS Urban Survival Handbook (29 page)

Read SAS Urban Survival Handbook Online

Authors: John Wiseman

Tags: #Health & Fitness, #Reference, #Survival, #Fiction, #Safety, #Self-Help, #Personal & Practical Guides, #General, #Survival Skills

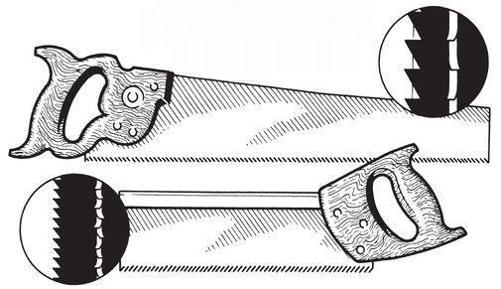

Saws

There is a wide variety of saws. They must be kept sharp (a dealer can arrange this for you) and rust-free. Saws with big teeth are intended to rip through softwood quickly—cutting on the downward stroke. Smaller teeth imply finer work—possibly for plywood or chipboard. The shape of the teeth may mean that more wood is removed on the downward stroke. A dealer will advise you for your specific needs.

Large teeth are intended to follow the grain—panel saws with about nine teeth to 25 mm (1 in) are more versatile.

Tenon saws, with small teeth-about 15 to 25 mm (1 in)-work well with or across the grain.

Tenon saws are for cutting joints in joinery (mortise-andtenon joints!) and fine work on smaller jobs requiring more care. Most have a strengthening bar along the top edge of the blade, which restricts the depth of cut, so you won’t be able to saw sheet materials.

REMEMBER

- ■

KEEP saws sharp, clean and oiled - ■

Avoid using saws which have been bent or buckled - ■

Hang up saws when not in use - ■

The saw is supposed to do most of the work—if you’re using excessive pressure, either the saw is blunt or it’s the wrong saw for the job - ■

ALWAYS saw on a steady surface and anchor the workpiece - ■

ALWAYS support as much of the wood as possible. When the waste wood falls (which you should avoid), the rest may topple off supports - ■

DON’T saw between two supports, allowing the wood to droop down at the cutting point. This will close the cutting line, gripping the saw - ■

Keep your fingers well away from the cutting line - ■

When starting a cut, you may need a thumb to stop the blade ‘jumping off’ the cut line. Start very slowly with light controlled strokes, until the blade is established in the wood

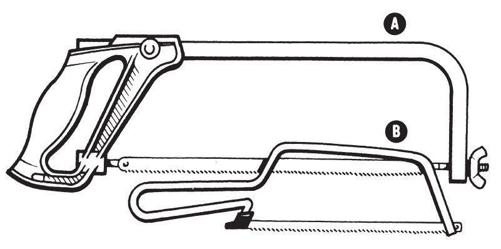

Hacksaws

A hacksaw (A) is a basic tool for cutting metal bars or strips, angle-iron, metal and plastic pipes. The frame holds the blade taut—don’t overtighten, you may cause it to snap. Some types allow for the blade to be set at different angles. The frame limits the depth of cut possible—when it hits the workpiece, you have gone as far as you can. It’s not suitable for sheet metal, unless you are making small straight cuts at the edges.

The blade should point downwards—away from the top frame—not upwards. Cutting pressure should be on the forward stroke (away from you). Keep your free hand on top of the frame, at the front (away from you) to steady and guide the saw. Try to use long controlled strokes. Try to anchor the workpiece in a vice.

Small hacksaws (B) are called ‘junior’ hacksaws. If you are cutting hard steel, they aren’t really strong enough.

Change blades regularly and ask a dealer for advice. There are different types and qualities of blade—usually with different size teeth—for different jobs or degrees of finish. NEVER use if the blade is twisted or cracked.

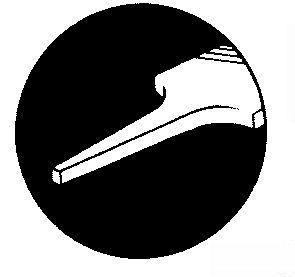

DANGER!

Unprotected tang.

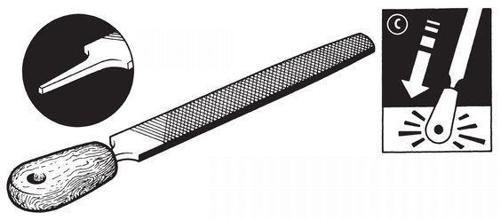

There is a wide range of files with different profiles-square, half-round, triangular. For very fine work, use needle files.

Rasps/files

Most are designed to remove material on the forward stroke. Some have removable handles—

NEVER

use without the handle! It’s quite possible to drive the unprotected point (tang) right into your hand. Tap the rasp/file handle downwards on the bench (C) to make sure the handle is secure. Hold the handle firmly, steadying the other end with the tips of your fingers. Use a steady even pressure. Don’t work fast—be patient and let the tool do the work. If the face of the tool becomes clogged, give it a good stiff brushing.

Craft knives

Basically a sturdy handle, which can be opened to allow a new blade to be fitted. Choose one that suits your grip. Retractable blade options are a good idea, if the knife is good quality. Blade covers that come with non-retractable types get lost, or don’t fit the other blade shapes that are available. The blade cover could also come off—in a pocket, perhaps!

ALWAYS change the blade as soon as it becomes inefficient. You shouldn’t have to use excessive pressure. The blade is supposed to do the work. ALWAYS buy the correct blades for the make of handle—a sloppy fit is no good. Some of the fancy/ specialist blade shapes are useful—but also quite deadly.

Some retractable knives accept ordinary reversible blades. Others allow you to snap off the blunt end as you go. For very fine work, scalpels offer precision and control.

NEVER twist or gouge with the blade. The tip might break and fly off. Remove material slowly—not in large chunks. ALWAYS remove the blade from non-retractable types when putting them away.

Smaller craft knives are advisable for smaller, or more delicate jobs. There’s a wide range available. You hold the handle more like a pencil—less like a weapon—and use a lot less pressure. Use the right tool for the right job!

REMEMBER

If throwing away knife blades, make sure you wrap them well to save nasty accidents. Picking up a rubbish bag, or brushing a leg against it, could cause a severe injury.

TOOL RULES

- ■

Always use a tool for the job it was designed to do - ■

Always use tools correctly—if it feels very awkward, STOP - ■

Keep hands and other parts of the body out of direct ‘line of fire’ - ■

DON’T use excessive force - ■

Keep ‘sharp’ tools SHARP - ■

Check all tools for strength and SAFETY - ■

Store all tools safely—out of the reach of children

POWER TOOLS

There’s a wide choice of makes and types of tool. The more expensive, top-of-the-range ones are usually intended for heavy-duty or professional use. The lower-priced should be fine for occasional home use—as long as they are of good quality. Often the first thing to fail, especially on drills, is the on/off switch from constant stopping and starting!

There’s a wide choice of makes and types of tool. The more expensive, top-of-the-range ones are usually intended for heavy-duty or professional use. The lower-priced should be fine for occasional home use—as long as they are of good quality. Often the first thing to fail, especially on drills, is the on/off switch from constant stopping and starting!

Power tools MUST be cleaned and serviced—how often depends on how often you use (or abuse) them. There are service departments of all the major manufacturers practically everywhere.

PLEASE NOTE

Read the following safety notes in conjunction with later information on specific power tools. These notes apply to almost all power tools.

Before you begin

REMEMBER

Always choose tools which are ‘double insulated’—with plastic casings.

The double-insulation symbol in most countries is two small squares, one inside the other.