Read Moon Lander: How We Developed the Apollo Lunar Module Online

Authors: Thomas J. Kelly

Tags: #Science, #Physics, #Astrophysics, #Technology & Engineering, #History

Moon Lander: How We Developed the Apollo Lunar Module (11 page)

One morning in early February 1963 I received phone call from my wife. I answered with apprehension because she rarely called me at work. She told me in an anxious voice that I should come home right away because my father had been in a serious accident. Outside in the cold, crisp air and bright sunshine, my mind raced ahead to dozens of possibilities, all of them bad. I knew Joan would not tell me to come home immediately unless it was very serious.

One look at Joan’s crestfallen face told me the worst. My father was dead from a heart attack while on his way to work on the Long Island Railroad. We had to go to the LIRR station in Jamaica, Queens, to identify his body. Shock settled over me, and I sat for a few moments clinging to Joan as both our eyes filled with tears. I pictured my Dad as I had seen him only two days earlier, when we visited my parents at my boyhood home in Merrick. We brought our four children with us: David, eight, Tommy, six, Edward, four, and Christopher, just two and a half years old. It was a lovely visit; both Mom and Dad played with the kids and enjoyed them fully.

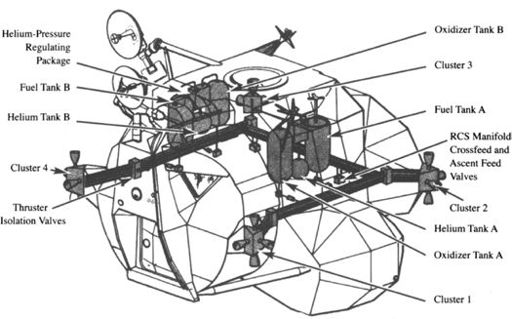

The reaction control system configuration. (Courtesy Northrop/Grumman Corporation) (

Illustration credit 5.1

)

At the Jamaica station Joan and I were ushered into a small room in the basement, and there was Dad stretched out on a wooden table, neatly dressed in his business suit, shirt, and tie. He looked like he was taking a catnap, and I hoped that he would open his eyes, get up, and come home with us. He looked healthy, certainly not dead. But he was dead, and I shook with sobs once again as the irreversibility of it all sank in.

The next four days were a blur of grieving, loving, and consolation from relatives and friends. Out-of-town relatives, including my brother and his wife from California and my aunt and cousin and her husband from upstate New York, stayed in the house with my mother, helping her perform the required rituals. My mother, brother, and I received condolences and support from our family, friends, and many people who had known my Dad. At last we laid him to rest with his mother and father in the family plot in Holy Cross Cemetery in Brooklyn and returned home to resume our lives.

My father’s sudden, unexpected death was a jolting reminder that life goes on despite the Apollo program. I had been so wrapped up in Grumman that I had lost contact with the “real world.” Dad’s passing reminded me that I must try to achieve a better balance of home and family life versus work. But my immediate response was just the opposite. In grieving for my Dad, I tried to escape his loss by plunging into my job with greater intensity. The quest to land on the Moon created its own reality, a place where we could isolate ourselves from the problems of everyday life, substituting an intriguing and different set of problems over which we had control.

Defining LM’s Basic Configuration

It was an exciting time to be on the LM program at Grumman, and after the immediacy of my mourning had subsided, I bounded into work each day full of enthusiasm. There were many wonderful work sessions that year (1963) in which we used our ingenuity and imagination to make our exotic spacecraft take shape. There were no precedents for what we were doing, so we were neither bound nor guided by convention. NASA allowed us most of the year to firm up the preliminary design and translate it into full-scale mockups.

I vividly recall one Saturday session in the conference room with Ozzie Williams, Bob Grossman, and others from the Reaction Control System Group. We were reexamining the RCS configuration, particularly the geometric placement of the sixteen thrusters on the ascent stage and the degree of redundancy. We spent most of the day at the blackboard, sketching different system configurations and thruster locations and tabulating the features of each arrangement, including weight, redundancy, and controllability after successive thruster failures. We argued engineering logic and practical issues, such as jet contamination effects on adjacent areas of the ascent stage. This latter consideration convinced us to abandon the originally proposed RCS configuration, which had four jets close to the front windows, likely to obscure the windows with rocket-exhaust products.

“Well, where does that leave us?” I challenged. ‘All the configurations we’ve looked at have some major drawback. Are there any others that we’ve missed?” I stood at the blackboard facing the group, all of them deep in concentration.

Bob Grossman jumped up and took the chalk from me, his face glowing. He vigorously erased the blackboard and began to sketch. “Here, how about this?” he said as he continued to sketch. “We’ll mount the thrusters at forty-five degrees, keeping them away from the windows. And we’ll arrange them as an axial pair and an orthogonal pair. Let’s see how that looks in our tables.”

Grossman was panting with excitement as he quickly filled in our comparison tables on the blackboard for this configuration. It looked better than any of the others, but we continued discussing its pros and cons for another

hour before choosing it as the preferred design arrangement: Four four-jet clusters located at forty-five degrees from the centerline of the crew cabin, with two of the jets aligned parallel to the main rocket engines’ thrust axis; the other two jets orthogonal and at ninety degrees to each other. The RCS was arranged in two totally redundant systems, A and B, each having a fuel, oxidizer, and helium tank, eight jet thrusters (two in each four-jet cluster), and fully redundant components. This system could maintain control about all three vehicle axes after any single failure and many selective double failures. We left the office that evening elated at having successfully solved a difficult puzzle and created something novel and valuable.

During this formative phase of the program I realized how fortunate I was to have two very talented assistants who worked effectively with each other and with me. Bob Carbee, LM Subsystems project engineer, was in charge of the design sections, and Arnold Whitaker, LM Systems project engineer, headed the analytical sections. Whitaker led Grumman’s proposal team for the navy’s TFX missile system and Carbee assisted him. The TFX competition, which included a subsonic attack airplane called the Missileer to carry the advanced missiles, was canceled by the navy in a change of planning direction while the missile proposals were being evaluated. The cancellation occurred as we were preparing the LM proposal, making Carbee and Whitaker available for key engineering positions on the LM program.

2

Bob Carbee was tall and athletically built, often smoking a straight, sporty pipe, which enhanced his 1950s movie star image. Nevertheless, Carbee was a down-to-earth design engineer with broad interests and curiosity. At Grumman he worked his way up from structural designer to armament group leader, then cockpit group leader, designing and integrating the cockpits with their controls, instrument panels, ejection seats, windshields, and plexiglas canopies. He led a newly formed Weapons Systems Section that cut across older design specialties to analyze, design, and integrate the airborne weapons systems into the aircraft and be responsible for their mission performance. For example, Carbee’s section was responsible for the overall accuracy of the A2F-1 Intruder’s attack system, the lethality of the Eagle missile system, and the operational effectiveness of the W2F-1 Hawkeye. To integrate these systems across disciplines Carbee became a practitioner of systems engineering, learning this field from the bottom up before the air force’s systems engineering manuals even existed. His breadth of systems design experience and exposure to a wide variety of missions and flight vehicles made the LM the next logical step in his career.

Carbee’s office reflected his wide-ranging interests. Engineering artifacts were everywhere—cutaways of bomb-release mechanisms, an escape-seat actuator, canopy locking latches, and so forth. Behind each item was a story about the technical issues that shaped its design. On his desk and walls were pictures of his life beyond Grumman. One was of a smooth-faced nineteen

year old posed in his leather flight jacket and overseas cap next to a sleek fighter plane. Carbee downed two German planes with his P-51 Mustang during the bloody campaign up the rugged boot of Italy. When I asked him about his wartime service, he modestly remembered being very young and very scared. Other photos showed his lovely wife Mary and two beautiful daughters.

Carbee was a competitive but good-humored sailor racing a seventeen-foot Mobjack weekends in the strong winds of Long Island’s Great South Bay. Always among the winners, on Mondays he often told us about his latest adventures, replete with knockdown gusts, hairbreadth recoveries, and a stirring finish.

The section heads who reported to Carbee admired and respected him. He helped them solve technical problems and gave sound advice regarding administrative and personnel matters. Once convinced that they were right, he backed up his people ferociously, tackling me, Rathke, or anyone else in the hierarchy to make sure their viewpoint was considered. He was tenacious in argument, seldom losing his temper unless severely provoked.

Carbee and I led some memorable design meetings in structures and propulsion to review and revise the configuration. The Grumman LM design as proposed just barely fit the constraints imposed by NASA at its estimated weight of twenty-two thousand pounds. When this increased to twenty-five thousand pounds during negotiations, the carefully constructed proposal design house of cards collapsed and had to be reinvented.

Arnold Whitaker was a brilliant systems engineer with an instinctive feel for how to solve problems through rigorous analyses that yielded pragmatic results. He was short, slim, and bald with flashing blue eyes and a sharply pointed nose, and his probing intellect was evident in his persuasive, logical approach to problem solving. Arnold had a disconcerting habit of thinking carefully and deliberately before he answered a question or presented an opinion.

Whitaker and Carbee were the same age, four years older than I. Whitaker served in the navy during World War II but never saw combat. An aeronautical engineer from MIT, he obtained a master’s in applied mathematics from Adelphi University. After a brief stint at Chance Vought Aircraft, Whitaker came to Grumman when Vought moved from Connecticut to Texas. He became group leader of Research Control Analysis, developing techniques for analyses of aircraft control systems. Swept-wing supersonic aircraft with hydraulically powered ailerons, elevators, flaps, and rudders demanded increased sophistication in mathematical analysis and computer simulation, and Whitaker was at the forefront of Grumman’s efforts in this area. He worked on problems that commanded attention throughout the industry, such as control surface flutter, control reversal at transonic speeds, and powered control system instabilities.

Whitaker was a forceful leader as well as a gifted analyst. He drove studies and analyses hard until they produced answers designers could use in practical

systems. He became project engineer for the Eagle missile, an advanced two-stage solid-rocket air-to-air weapon won by Grumman in a navy competition. I remember him analyzing a missile separation dynamics problem at the blackboard with his project group leaders, filling the board with sketches and equations, striding back and forth, head down, thinking, stabbing the air with his cigarette when offering a new approach: an impressive performance that left each participant with an assignment and due date for his part of the puzzle.

The navy canceled the Eagle project just before it was to enter flight testing due to a change in strategic planning direction. It decided to have a compatible series of airborne missiles to perform various missions, launched from a subsonic missile-carrying airplane called the Missileer. Whitaker went from leading a real project to heading Grumman’s proposal team for its successor, the TFX(N) missile.

Whitaker played a major role in all aspects of LM Engineering because the analytical sections, including Systems Analysis and Integration, Structural Analysis, Thermal, Weights, Dynamic Analysis, Electronics, and Systems Test, were under his leadership. He and Bob Carbee contributed to many of the most creative sessions during which the LM design took shape and matured.

The LM proposal configuration had cylindrical structure in the ascent and descent stages and a five-legged fixed landing gear. The descent-stage structure housed the descent propulsion system (DPS), the main elements of which were the descent rocket engine, six spherical propellant tanks (three fuel and three oxidizer), three spherical helium pressurant tanks, and associated plumbing. The descent stage also supported the landing gear, provided compartments to carry scientific equipment to be deployed on the Moon, and carried the landing radar. The ascent-stage structure contained the ascent propulsion system, consisting of ascent rocket engine, four spherical propellant tanks (two each fuel and oxidizer), a spherical helium pressurant tank and associated plumbing, and the reaction control system, which had sixteen small rocket thrusters mounted in clusters of four, plus spherical fuel, oxidizer, and pressurant tanks. The ascent stage also housed the crew compartment with its seats, instrument panels, controls, and helicopter bubble windows; the electrical power system (EPS), with its fuel cells, hydrogen and oxygen tanks, busses, and switchgear; the environmental control system, with its water and oxygen tanks, fans, and plumbing; and all the electronic systems, including GNC, communications (with steer able and omnidirectional antennas), instrumentation, and rendezvous radar. The ascent stage had two docking hatches into the crew compartment, one upper (or overhead) and one forward. All this was squeezed into a package so tight that the least change of ground rules or assumptions would cause it to burst.