Read The Goal: A Process of Ongoing Improvement Online

Authors: Eliyahu Goldratt

The Goal: A Process of Ongoing Improvement (25 page)

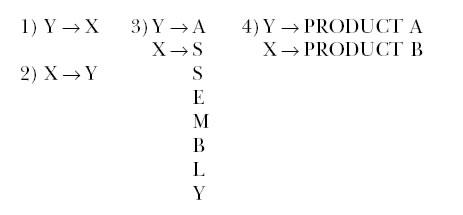

Y --> X Product parts are what join the two in a relationship with each other, Jonah explains, and the arrow obviously indicates the flow of parts from one to the other. He adds that we can consider

any

non-bottleneck feeding parts to X, because no matter which one we choose, its inventory must be processed at some subsequent point in time by X.

"By the definition of a non-bottleneck, we know that Y has extra capacity. Because of its extra capacity, we also know that Y will be faster in filling the demand than X,’’ says Jonah. "Let’s say both X and Y have 600 hours a month available for production. Because it is a bottleneck, you will need all 600 hours of the X machine to meet demand. But let’s say you need only 450 hours a month, or 75 percent, of Y to keep the flow equal to demand. What happens when Y has worked its 450 hours? Do you let it sit idle?’’

Bob says, "No, we’ll find something else for it to do.’’ "But Y has already satisfied market demand,’’ says Jonah. Bob says, "Well, then we let it get a head start on next month’s work.’’

"And if there is nothing for it to work on?’’ asks Jonah. Bob says, "Then we’ll have to release more materials.’’ "And

that

is the problem,’’ says Jonah. "Because what happens to those extra hours of production from Y? Well, that inventory has to go somewhere. Y is faster than X. And by keeping Y active, the flow of parts to X must be greater than the flow of parts leaving X. Which means . . .’’

He walks over to the work-in-process mountain and makes a sweeping gesture.

"You end up with all this in front of the X machine,’’ he says. "And when you’re pushing in more material than the system can convert into throughput, what are you getting?’’

"Excess inventory,’’ says Stacey.

"Exactly,’’ says Jonah. "But what about another combination? What happens when X is feeding parts to Y?’’

Jonah writes that on the floor with the chalk like this...

X --> Y

"How much of Y’s 600 hours can be used productively here?’’ asks Jonah.

"Only 450 hours again,’’ says Stacey.

"That’s right,’’ says Jonah. "If Y is depending exclusively upon X to feed it inventory, the maximum number of hours it can work is determined by the output of X. And 600 hours from X equates to 450 hours for Y. After working those hours, Y will be starved for inventory to process. Which, by the way, is quite acceptable.’’

"Wait a minute,’’ I say. "We have bottlenecks feeding nonbottlenecks here in the plant. For instance, whatever leaves the NCX-10 will be processed by a non-bottleneck.’’

"From other non-bottlenecks you mean. And do you know what happens when you keep Y active that way?’’ asks Jonah. "Look at this.’’

He draws a third diagram on the floor with the chalk.

Y →A X→S S E M B L Y

In this case, Jonah explains, some parts do not flow through a bottleneck; their processing is done only by a non-bottleneck and the flow is directly from Y to assembly. The other parts

do

flow through a bottleneck, and they are on the X route to assembly where they are mated to the Y parts into a finished product.

In a real situation, the Y route probably would consist of one non-bottleneck feeding another non-bottleneck, feeding yet another non-bottleneck, and so on, to final assembly. The X route might have a series of non-bottlenecks feeding a bottleneck, which in turn feeds a chain of more non-bottlenecks. In our case, Jonah says, we’ve got a group of non-bottleneck machines downstream from X which can process parts from either the X or the Y route.

"But to keep it simple, I’ve diagrammed the combination with the fewest number of elements—one X and one Y. No matter how many non-bottlenecks are in the system, the result of activating Y just to keep it busy is the same. So let’s say you keep both X and Y working continuously for every available hour. How efficient would the system be?’’

"Super efficient,’’ says Bob.

"No, you’re wrong,’’ says Jonah. "Because what happens when all this inventory from Y reaches final assembly?’’

Bob shrugs and says, "We build the orders and ship them.’’

"How can you?’’ asks Jonah. "Eighty percent of your products require at least one part from a bottleneck. What are you going to substitute for the bottleneck part that hasn’t shown up yet?’’

Bob scratches his head and says, "Oh, yeah ...I forgot.’’

"So if we can’t assemble,’’ says Stacey, "we get piles of inventory again. Only this time the excess inventory doesn’t accumulate in front of a bottleneck; it stacks up in front of final assembly.’’

"Yeah,’’ says Lou, "and another million bucks sits still just to keep the wheels turning.’’

And Jonah says, "You see? Once more, the non-bottleneck does not determine throughput, even if it works twenty-hour hours a day.’’

Bob asks, "Okay, but what about that twenty percent of products

without

any bottleneck parts? We can still get high efficiencies with them.’’

"You think so?’’ asks Jonah.

On the floor he diagrams it like this...

Y →PRODUCT A X→PRODUCT B

This time, he says, the X and Y operate independently of one another. They are each filling separate marketing demands.

"How much of Y’s 600 hours can the system use here?’’ asks Jonah.

"All of ’em,’’ says Bob.

"Absolutely not,’’ says Jonah. "Sure, at first glance it looks as if we can use one hundred percent of Y, but think again.’’

"We can only use as much as the market demand can absorb,’’ I say.

"Correct. By definition, Y has excess capacity,’’ says Jonah. "So if you work Y to the maximum, you once again get excess inventory. And this time you end up, not with excess work-inprocess, but with excess finished goods. The constraint here is not in production. The constraint is marketing’s ability to sell.’’

As he says this, I’m thinking to myself about the finished goods we’ve got crammed into warehouses. At least two-thirds of those inventories are products made entirely with non-bottleneck parts. By running non-bottlenecks for "efficiency,’’ we’ve built inventories far in excess of demand. And what about the remaining third of our finished goods? They have bottleneck parts, but most of those products have been sitting on the shelf now for a couple of years. They’re obsolete. Out of 1,500 or so units in stock, we’re lucky if we can sell ten a month. Just about all of the

competitive

products with bottleneck parts are sold virtually as soon as they come out of final assembly. A few of them sit in the warehouse a day or two before they go to the customer, but due to the backlog, not many.

I look at Jonah. To the four diagrams on the floor, he has now added numbers so that together they look like this...

Jonah says, "We’ve examined four linear combinations involving X and Y. Now, of course, we can create endless combinations of X and Y. But the four in front of us are fundamental enough that we don’t have to go any further. Because if we use these like building blocks, we can represent

any

manufacturing situation. We don’t have to look at trillions of combinations of X and Y to find what is universally true in all of them; we can generalize the truth simply by identifying what happens in each of these four cases. Can you tell me what you have noticed to be similar in all of them?’’

Stacey points out immediately that in no case does Y ever determine throughput for the system. Whenever it’s possible to activate Y above the level of X, doing so results only in excess inventory, not in greater throughput.

"Yes, and if we follow that thought to a logical conclusion,’’ says Jonah, "we can form a simple rule which will be true in every case: the level of utilization of a non-bottleneck is not determined by its own potential, but by some other constraint in the system.’’

He points to the NCX-10.

"A major constraint here in your system is this machine,’’ says Jonah. "When you make a non-bottleneck do more work than this machine, you are not increasing productivity. On the contrary, you are doing exactly the opposite. You are creating excess inventory, which is against the goal.’’

"But what are we supposed to do?’’ asks Bob. "If we don’t keep our people working, we’ll have idle time, and idle time will lower our efficiencies.’’

"So what?’’

asks Jonah.

Donovan is taken aback. "Beg pardon, but how the hell can you say that?’’

"Just take a look behind you,’’ says Jonah. "Take a look at the monster you’ve made. It did not create itself. You have created this mountain of inventory with your own decisions. And why? Because of the wrong assumption that you must make the workers produce one hundred percent of the time, or else get rid of them to ‘save’ money.’’

Lou says, "Well, granted that maybe one hundred percent is unrealistic. We just ask for some acceptable percentage, say, ninety percent.’’

"Why is ninety percent acceptable?’’ asks Jonah. "Why not sixty percent, or twenty-five? The numbers are meaningless unless they are based upon the constraints of the system. With enough raw materials, you can keep one worker busy from now until retirement. But

should

you do it? Not if you want to make money.’’

Then Ralph suggests, "What you’re saying is that making an employee work and profiting from that work are two different things.’’

"Yes, and that’s a very close approximation of the second rule we can logically derive from the four combinations of X and Y we talked about,’’ says Jonah. "Putting it precisely, activating a resource and utilizing a resource are not synonymous.’’

He explains that in both rules, "utilizing’’ a resource means making use of the resource in a way that moves the system toward the goal. "Activating’’ a resource is like pressing the ON switch of a machine; it runs whether or not there is any benefit to be derived from the work it’s doing. So, really, activating a non-bottleneck to its maximum is an act of maximum stupidity.

"And the implication of these rules is that we must

not

seek to optimize every resource in the system,’’ says Jonah. "A system of local optimums is not an optimum system at all; it is a very inefficient system.’’

"Okay,’’ I say, "but how does knowing this help us get the missing parts unstuck at the milling machines and moved to final assembly?’’

Jonah says, "Think about the build-up of inventory both here and at your milling machines in terms of these two rules we just talked about.’’

"I think I see the cause of the problem,’’ Stacey says, "We’re releasing material faster than the bottlenecks can process it.’’

"Yes,’’ says Jonah. "You are sending work onto the floor whenever

non

bottlenecks are running out of work to do.’’

I say, "Granted, but the milling machines are a bottleneck.’’

Jonah shakes his head and says, "No, they are not—as evidenced by all this excess inventory behind you. You see, the milling machines are not intrinsically a bottleneck.

You

have turned them into one.’’

He tells us that with an increase in throughput, it is possible to create new bottlenecks. But most plants have so much extra capacity that it takes an enormous increase in throughput before this happens. We’ve only had a twenty percent increase. When I had talked to him by phone, he thought it unlikely a new bottleneck would have occurred.

What happened was that even as throughput increased, we continued loading the plant with inventory as if we expected to keep all our workers fully activated. This increased the load dumped upon the milling machines and pushed them beyond their capacity. The first-priority, red-tagged parts were processed, but the green-tagged parts piled up. So not only did we get excess inventory at the NCX-10 and at heat-treat, but due to the volume of bottleneck parts, we clogged the flow at another work center and prevented non-bottleneck parts from reaching assembly.

When he’s finished, I say, "All right, I see now the error of our ways. Can you tell us what we should do to correct the problem?’’

"I want you all to think about it as we walk back to your conference room and then we’ll talk about what you should do,’’ says Jonah. "The solution is fairly simple.’’

Just how simple the solution is doesn’t become apparent to me until I’m home that night. I’m sitting at the kitchen table with a pad of paper and a pencil thinking about what was suggested today when Sharon comes in.

"Hi,’’ she says as she sits down.

"Hi,’’ I say back. "What’s up?’’

"Not much,’’ she says. "Just wondered what you were doing.’’

"I’m working,’’ I tell her.

"Can I help?’’ she asks.

"Well...I don’t know,’’ I say. "It’s kind of technical. I think you’ll probably be bored by it.’’

"Oh,’’ she says. "Does that mean you want me to leave?’’ Guilt strikes.

"No, not if you want to stay,’’ I tell her. "Do you want to try to solve a problem?’’

"Okay,’’ she says, brightening.

I say, "All right. Let me think of how to put this to you. Do you know about the scout hike Dave and I were on?’’ "She doesn’t, but I do!’’ says Dave, racing into the kitchen.

He skids to a stop on the smooth floor and says, "Sharon doesn’t know anything about the hike. But I can help you.’’ I say, "Son, I think there is a career for you in sales.’’ Sharon indignantly says, "Yes, I

do

know about the hike.’’ "You weren’t even there,’’ says Dave.

"I’ve heard everybody talk about it,’’ she says.

"Okay,

both

of you can work on this,’’ I say. "Here’s the problem: We’ve got a line of kids on a hike in the woods. In the middle of the line, we’ve got Herbie. We’ve already taken the pack off Herbie’s back to help him go faster, but he’s still the slowest. Everybody wants to go faster than Herbie. But if that happens, the line will spread out and some of the kids will get lost. For one reason or another, we can’t move Herbie from the middle of the line. Now, how do we keep the line from spreading?’’

They both become thoughtful.

I say, "All right, now both of you go into the other room. I’ll give you ten minutes, and then we’ll see which one of you comes up with the best idea to keep everyone together in the line.’’ "What does the winner get?’’ asks Dave.

"Well... anything within reason.’’

"Anything?’’

asks Sharon.

"Within reason,’’

I repeat.

So they leave and I get about ten minutes of peace and quiet.

Then I see the two faces looking around the corner. "Ready?’’ I ask.

They come in and sit down at the kitchen table with me. "Want to hear my idea?’’ asks Sharon.

"My idea is better,’’ says Dave.

"It is not!’’ she tells him.

"Okay, enough!’’ I say. "What’s your idea, Sharon?’’ Sharon says, "A drummer.’’

"Pardon me?’’

"You know...like in a parade,’’ she says.

"Oh, I know what you mean,’’ I say, realizing what she has in mind. "There aren’t any gaps in a parade. Everybody is marching in step.’’

Sharon beams. Dave gives her a dirty look.

"So everybody’s marching in step . . . to a beat,’’ I say, thinking out loud. "Sure. But how do you keep the people in front of Herbie from setting a faster pace?’’

"You have Herbie beat the drum,’’ says Sharon. I think about it and say, "Yeah, that’s not bad.’’ "But my idea is better,’’ says Dave.

I turn to him. "Okay, wise guy, what’s your idea?’’ "Tie ropes to everyone,’’ says Dave.

"Ropes?’’

"You know, like mountain climbers,’’ he says. "You tie everyone together at the waist with one long rope. So, that way, no one could get left behind, and nobody could speed up without everybody speeding up.’’

I say, "Hmmm... that’s very good.’’

It would mean that the line—which would translate to the total inventory in the plant—could never be longer than the rope. And the rope, of course, could be of a pre-determined length, which means we could control it with precision. Everyone would have to walk at the same speed. I look at Dave, a little in awe of his creativity.

"Come to think of it, the rope makes it sound like having physical links between all the equipment,’’ I tell him, "which is like an assembly line.’’

"Yeah, an assembly line,’’ says Dave. "Didn’t you tell me once that an assembly line is supposed to be the best way to make things?’’

"Well, yes, it’s the most efficient way to manufacture,’’ I say.

"In fact, we use that approach when we do the final assembly for most of our products. The problem is that an assembly line won’t work throughout the whole plant.’’

"Oh,’’ says Dave.

"But those are both good ideas you two thought up,’’ I tell them. "In fact, if we changed each of your ideas just a little bit we’d almost have the solution suggested to us today.’’ "Like how?’’ asks Sharon.

"See, to keep the line from spreading, it actually wouldn’t be necessary to keep everyone marching to exactly the same step or to keep everyone tied to the rope,’’ I tell them. "What we really have to do is just keep the kid at the front of the line from walking faster than Herbie. If we can do that, then everybody will stay together.’’

"So we just tie the rope from Herbie to the kid at the front,’’ says Dave.

"Or, maybe Herbie and the boy at the front of the line have signals,’’ says Sharon. "When the boy in front goes too fast, Herbie tells him to wait or slow down.’’

"That’s right,’’ I say. "Both of you figured it out.’’ "So what do we

both

win?’’ asks Sharon.

"What do you want?’’ I ask. "A pizza with everything? A night at the movies?’’

They’re quiet for a moment.

"The movies sound good,’’ says Sharon, "but what I’d really like is if you could get Mom to come home again.’’

Now it gets very quiet.

Dave says finally, "But if you can’t, we’ll understand.’’ "Well, I’m doing my best,’’ I say. "Meanwhile, how about the movies?’’

After the kids have gone to bed, I sit up wondering for the hundredth time whether Julie will come back. Compared with my marital difficulties, the inventory problem at the plant seems simple—or at least it seems simple now. I guess every problem is easy once you’ve figured it out.

We are, in effect, going to do what my two kids came up with. The Herbies (the bottlenecks) are going to tell us when to let more inventory into the system—except we’re going to use the aid of computers instead of drums and ropes.

After we returned to the conference room in the office building today, we started talking, and we all agreed that we’re obviously releasing too much material. We don’t need five or six weeks of inventory in front of the bottleneck to keep it productive.

"If we can withhold materials for red parts, instead of pushing them out there as soon as the first non-bottleneck has nothing to do,’’ said Stacey, "the milling machines will then have time to work on the green parts. And the parts we’re missing will reach assembly with no problem.’’

Jonah nodded and said, "That’s right. What you have to do is find a way to release the material for the red parts according to the rate at which the bottlenecks need material—and strictly at that rate.’’

Then I said, "Fine, but how do we time each release of material so it arrives at the bottleneck when it’s needed?’’ Stacey said, "I’m not sure, but I see what you’re worried about. We don’t want the opposite problem of no work in front of the bottleneck.’’

"Hell, we got at least a month before that happens, even if we released no more red tags from today on,’’ said Bob. "But I know what you mean. If we idle the bottleneck, we lose throughput.’’

"What we need,’’ I said, "is some kind of signal to link the bottlenecks with the release-of-materials schedule.’’

Then Ralph, to my surprise, spoke up and said, "Excuse me, this is just a thought. But maybe we can predict when to release material by some kind of system based on the data we’ve kept on both the bottlenecks.’’

I asked him what he was getting at.

He said, "Well, since we started keeping data on the bottlenecks, I’ve been noticing I’m able to predict several weeks in advance what each bottleneck will be working on at a particular time. See, as long as I know exactly what’s in queue, I just take the average setup and process times for each type of part, and I’m able to calculate when each batch should clear the bottleneck. Because we’re only dealing with one work center, with much less dependency, we can average the statistical fluctuations and get a better degree of accuracy.’’

Ralph went on to say that he knows from observation it takes about two weeks, plus or minus a day or two, for material to reach the bottlenecks from the first operations.

"So by adding two weeks to the setup and process times of what’s in queue at the bottleneck,’’ said Ralph, "I know how long it will take until the bottleneck is actually working on material we release. And as each batch leaves the bottleneck, we can update our information and calculate a date when Stacey should release more red-tag material.’’

Jonah looked at Ralph and said, "that’s excellent!’’

"Ralph,’’ I said, "that’s terrific. How accurate do you really think we can be with this?’’

"I’d say we’d be accurate to within plus or minus a day,’’ he said. "So if we keep, say, a three-day stock of work-in-process in front of each bottleneck, we should be safe.’’

Everyone was telling Ralph how impressed they were when Jonah said, "But, in fact, Ralph, you can do much more than that with the same information.’’

"Like what?’’ asked Ralph.

Jonah said, "You can also attack the inventory problems in front of assembly.’’

"You mean we not only can do something about excess inventory on the bottleneck parts, but on the non-bottleneck parts as well?’’ I asked.

"Exactly,’’ said Jonah.

But Ralph said, "Sorry, folks, I’m not sure how I’d do that.’’

Then Jonah explained it to him—and all of us. If Ralph can determine a schedule for releasing red-tag materials based on the bottlenecks, he can also determine a schedule for final assembly.

Once he knows when the bottleneck parts will reach final assembly, he can calculate backwards and determine the release of the non-bottleneck materials along each of their routes. In this way, the bottlenecks will be determining the release of all the materials in the plant.

I said, "You know, that’s going to produce the same effect as moving the bottlenecks to the head of production, which is what I’d intended for us to do.’’

“Yeah, it sounds good,” said Ralph. “But I have to warn you, I can’t say how long it’ll take before I can do all that. I mean, I can have schedule for the red-tagged materials worked out in a fairly short order. The rest of it will take awhile.”

"Aw, come on, Ralphie,’’ said Bob, "a computer wiz like you ought to be able to crank that out in no time.’’

"I can crank something out in no time,’’ said Ralph, "but I’m not going to promise it’ll work.’’

I told him, "Relax; as long as we ease the load on the milling machines, we’ll be okay for the short haul. That’ll give you the time to get something basic in place.’’

"You may feel you have the time now to relax,’’ said Jonah, "but I have to catch a plane for Chicago in thirty-five minutes.’’ "Oh, shit,’’ I muttered, automatically glancing at my watch.

"I guess we’d better move.’’

It was not a graceful parting. Jonah and I ran out of the building, and I broke numerous speed limits—without incident—getting him to the airport.

"I have, shall we say, a special interest in plants like yours,’’ said Jonah. "So I’d appreciate it if you’d keep me informed of what happens.’’

"Sure,’’ I told him. "No problem. In fact, I’d planned on it.’’ "Good,’’ said Jonah. "I’ll be talking to you.’’

And with that he was out of the car and, with a wave, was sprinting through the terminal doors. I didn’t get a call, so I suppose he made it.