Read The Goal: A Process of Ongoing Improvement Online

Authors: Eliyahu Goldratt

The Goal: A Process of Ongoing Improvement (17 page)

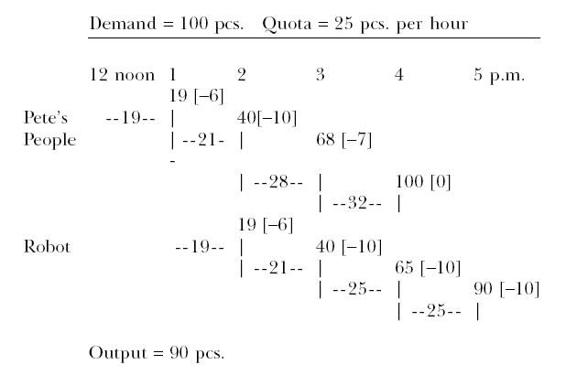

"Every time Pete’s area got behind, it was passed on to the robot,’’ I say. "But when Pete delivered 28 pieces, the robot could still only do twenty-five. That meant that when the final delivery of thirty-two pieces arrived at four o’clock, the robot still had three pieces to work on from the last batch. So it couldn’t start on the final batch right away.’’

"Okay, I see now,’’ says Bob.

Fred says, "You know, the most Pete was ever behind was ten pieces. Kind of funny how that’s exactly the number of pieces we ended up short.’’

"That’s the effect of the mathematical principle I was trying to explain this morning,’’ I say. "The maximum deviation of a preceding operation will become the starting point of a subsequent operation.’’

Bob reaches for his wallet.

"Well, I guess I owe

you

ten bucks,’’ he says to me. "Tell you what,’’ I say. "Instead of paying me, why don’t you give the money to Pete so he can spring for a round of coffee or something for the people in his department—just a little way to say thanks for the extra effort this afternoon.’’

"Yeah, right, that’s a good idea,’’ says Bob. "Listen, sorry we

couldn’t ship today. Hope it doesn’t get us in trouble.’’ "We can’t worry about it now,’’ I tell him. "The gain we made today is that we learned something. But I’ll tell you one thing: we’ve got to take a close look at our incentives here.’’ "How come?’’ asks Bob.

"Don’t you see? It didn’t matter that Pete got his hundred pieces done, because we still couldn’t ship,’’ I say. "But Pete and his people thought they were heroes. Ordinarily,

we

might have thought the same thing. That isn’t right.’’

When I get home that evening, both of the kids greet me at the door. My mother is in the background, with steam pouring out of the kitchen. I presume it has something to do with dinner and that she has everything under control. In front of me, Sharon’s face is beaming up at me.

"Guess what!’’ she says.

"I give up,’’ I say.

"Mommy called on the phone,’’ Sharon says.

"She did!’’ I say.

I glance up at my mother. She shakes her head. "Davey answered the phone,’’ she says. "I didn’t talk to her.’’ I look down at Sharon. "So what did Mommy say?’’ "She said she loved Davey and me,’’ says Sharon. "And she said she would be away for a while,’’ adds Davey.

"But that we shouldn’t worry about her.’’

"Did she say when she would be coming back?’’ I ask. "I asked her that,’’ says Davey. "But she said she couldn’t say right now.’’

"Did you get a phone number so I can call her back?’’ I ask him.

He looks down at the floor.

"David! You were supposed to ask her for the number if she called!’’

He mumbles, "I did, but . . . she didn’t want to give it to me.’’

"Oh,’’ I say.

"Sorry, Dad.’’

"It’s okay, Dave. Thanks for trying.’’

"Why don’t we all sit down to dinner,’’ my mother says cheerily.

This time the meal is not silent. My mother talks, and she does her best to cheer us up. She tells us stories about the Depression and how lucky we are to have food to eat.

Tuesday morning is a little bit more normal. Joining efforts, my mother and I manage to get the kids to school and me to work on time. By 8:30, Bob, Stacey, Lou, and Ralph are in my office, and we’re talking about what happened yesterday. Today, I find them much more attentive. Maybe it’s because they’ve seen the proof of the idea take place on their own turf, so to speak.

"This combination of dependency and fluctuations is what we’re up against every day,’’ I tell them. "I think it explains why we have so many late orders.’’

Lou and Ralph are examining the two charts we made yesterday. "What would have happened if the second operation hadn’t been a robot, if it had been some kind of job with people?’’ asks Lou.

"We would have had another set of statistical fluctuations to complicate things,’’ I say. "Don’t forget we only had two operations here. You can imagine what happens when we’ve got dependency running through ten or fifteen operations, each with its own set of fluctuations, just to make one part. And some of our products involve hundreds of parts.’’

Stacey is troubled. She asks, "Then how can we ever control what’s going on out there?’’

I say, "That’s the billion-dollar question: how can we control the fifty-thousand or—who knows?—maybe it’s fifty-million variables which exist in this plant?’’

"We’d have to buy a new

super

computer just to keep track of all of them,’’ says Ralph.

I say, "A new computer wouldn’t save us. Data management alone isn’t going to give us more control.’’

"What about longer lead times?’’ asks Bob.

"Oh, you really think longer lead time would have guaranteed our ability to ship that order to Hilton Smyth’s plant?’’ I ask him. "How long had we already known about that order before yesterday, Bob?’’

Bob wiggles back and forth. "Hey, all I’m saying is that we’d have some slop in there to make up for the delays.’’

Then Stacey says, "Longer lead times increase inventory, Bob. And that isn’t the goal.’’

"Okay, I know that,’’ Bob is saying. "I’m not fighting you. The only reason I mention the lead times is I want to know what we do about all this.’’

Everybody turns to me.

I say, "This much is clear to me. We have to change the way we think about production capacity. We cannot measure the capacity of a resource in isolation. Its true productive capacity depends upon where it is in the plant. And trying to level capacity with demand to minimize expenses has really screwed us up. We shouldn’t be trying to do that at all.’’

"But that’s what everybody else does,’’ says Bob. "Yes, everybody does. Or claims to. As we now can see, it’s a stupid thing to try,’’ I say.

"So how do other manufacturers survive?’’ asks Lou. I tell him I was wondering that myself. What I suspect is that as a plant comes close to being balanced through the efforts of engineers and managers doing the wrong things, events head toward a crisis and the plant is very quickly

un

balanced by shifting workers or by overtime or by calling back some people from layoff. The survival incentive overrides false beliefs. "Okay, but again, what are we going to do?’’ asks Bob. "We can’t hire without division approval. And we’ve even got a policy against overtime.’’

"Maybe it’s time to call Jonah again,’’ says Stacey. And I say, "I think maybe you’re right.’’

It takes Fran half an hour to locate the area of the world where Jonah happens to be today, and another hour passes before Jonah can get to the phone to talk to us. As soon as he’s on the line, I have another secretary round up the staff again and corral them in my office so we can hear him on a speaker phone. While they’re coming in, I tell Jonah about the hike with Herbie where I discovered the meaning of what he was telling me, and what we’ve learned about the effects of the two phenomena in the plant.

"What we know now,’’ I tell him, "is that we shouldn’t be looking at each local area and trying to trim it. We should be trying to optimize the whole system. Some resources have to have more capacity than others. The ones at the end of the line should have more than the ones at the beginning—sometimes a lot more. Am I right?’’

"You’re on the money,’’ says Jonah.

"Good. Glad to hear we’re getting somewhere,’’ I say. "Only the reason I called is, we need to know where to go from here.’’ He says, "What you have to do next, Alex, is distinguish between two types of resources in your plant. One type is what I call a bottleneck resource. The other is, very simply, a non-bottleneck resource.’’

I whisper to everybody to start taking some notes on this. "A bottleneck,’’ Jonah continues, "is any resource whose capacity is equal to or

less than

the demand placed upon it. And a non-bottleneck is any resource whose capacity is greater than the demand placed on it. Got that?’’

"Right,’’ I tell him.

"Once you have recognized these two types of resources,’’ says Jonah, "you will begin to see vast implications.’’

"But, Jonah, where does market demand come in?’’ Stacey asks. "There has to be some relationship between demand and capacity.’’

He says, "Yes, but as you already know, you should not balance

capacity

with demand. What you need to do instead is balance the

flow of product

through the plant with demand from the market. This, in fact, is the first of nine rules that express the relationships between bottlenecks and non-bottlenecks and how you should manage your plant. So let me repeat it for you: Balance flow, not capacity.’’

Stacey is still puzzled. She says, "I’m not sure I understand. Where do the bottlenecks and non-bottlenecks come into the picture?’’

Jonah says, "Let me ask you: which of the two types of resources determines the effective capacity of the plant?’’

"It would have to be the bottleneck,’’ she says.

I say, "That’s right. It’s like the kid on that hike last weekend —Herbie. He had the least capacity and he was the one who actually determined how fast the troop as a whole could move.’’

"So where should you balance the floor?’’ asks Jonah.

"Oh, I see,’’ says Stacey. "The idea is to make the flow through the bottleneck equal to demand from the market.’’

"Basically, yes, you’ve got it,’’ says Jonah. "Actually, the flow should be a tiny bit less than the demand.’’

"How come?’’ asks Lou.

"Because if you keep it equal to demand and the market demand goes down, you’ll lose money,’’ says Jonah. "But that’s a fine point. Speaking fundamentally, the bottleneck flow should be on a par with demand.’’

Bob Donovan is now making various noises, trying to get into the conversation.

"Excuse me, but I thought bottlenecks were bad,’’ says Bob. "They ought to be eliminated where possible, right?’’ "No, bottlenecks are not necessarily bad—or good,’’ says Jonah, "they are simply a reality. What I am suggesting is that where they exist, you must then use them to control the flow through the system and into the market.’’

That makes sense to me as I’m listening, because I’m remembering how I used Herbie to control the troop during the hike.

"Now I have to run,’’ says Jonah, "because you caught me during a ten-minute break in a presentation.’’

I jump in. "Jonah, before you go—!’’

"Yes?’’

"What’s our next step?’’

He says, "Well, first of all, does your plant have any bottlenecks?’’

"We don’t know,’’ I tell him.

"Then that’s your next step,’’ he says. "You have to find this out, because it makes an enormous difference in how you manage your resources.’’

"How do we find the bottlenecks?’’ says Stacey.

"It’s very simple, but it would take a few minutes to explain. Look, try to figure that out for yourselves,’’ says Jonah. "It’s really easy to do if you think about it first.’’

I say, "Okay, but....’’

"Good-bye for now,’’ he says. "Call me when you know if you have a bottleneck.’’

The speaker phone issues a click, followed by a fuzzy hum.

"Well... what now?’’ asks Lou.

"I guess we look at all our resources,’’ I say, "and compare them against market demand. If we find one in which demand is greater than capacity, then we’ll know we’ve got a bottleneck.’’

"What happens if we find one?’’ asks Stacey.

"I guess the best thing to do would be what I did to the scout troop,’’ I say. "We adjust capacity so the bottleneck is at the front of production.’’

"My question,’’ Lou says, "is what happens if our resource with the least capacity in fact has a capacity greater than what market demand calls for?’’

"Then I guess we’d have something like a bottle without a neck,’’ I say.

"But there would still be limits,’’ says Stacey. "The bottle would still have walls. But they’d be greater than the market demand.’’

"And if that’s the case?’’ asks Lou.

"I don’t know,’’ I tell him. "I guess the first thing to do is find out if we’ve got a bottleneck.’’

"So we go look for Herbie,’’ says Ralph. "If he’s out there.’’

"Yeah, quick, before we talk ourselves to death,’’ says Bob.

I walk into the conference room a few days later and there’s paper everywhere. The main table is covered with computer print-outs and binders. Over in the corner, a data terminal has been installed; next to it, a printer is churning out even more paper. The wastebaskets are full. So are all the ashtrays. The litter of white styrofoam coffee cups, empty sugar packets and creamer containers, napkins, candy bar and cracker wrappers, and so on is scattered about. What has happened is the place has been turned into our headquarters in the search for Herbie. We have not found him yet. And we’re getting tired.

Sitting at the far end of the main table is Ralph Nakamura. He and his data processing people, and the system data base they manage, are essential to the search.

Ralph does not look happy as I come in. He’s running his skinny fingers through his thinning black hair.

"This isn’t the way it’s supposed to be,’’ he’s saying to Stacey and Bob.

"Ahh, perfect timing,’’ says Ralph when he sees me. "Do you know what we just did?’’

"You found Herbie?’’ I say.

Ralph says, "No, we just spent two and a half hours calculating the demand for machines that don’t exist.’’

"Why’d you do that?’’

Ralph starts to sputter. Then Bob stops him.

"Wait, wait, wait a minute. Let me explain,’’ says Bob. "What happened was they came across some routings which still listed some of the old milling machines as being part of the processing. We don’t use them—’’

"Not only don’t we use them, just found out we sold them a year ago,’’ says Ralph.

"Everybody down in that department knows those machines aren’t there anymore, so it’s never been a problem,’’ says Bob.

So it goes. We’re trying to calculate demand for every resource, every piece of equipment, in the plant. Jonah had said a bottleneck is any resource which is equal to or less than the market demand placed on it. To find out if we’ve got one then, we concluded we first would have to know the total market demand for products coming out of this plant. And, second, we would have to find out how much time each resource has to contribute toward filling the demand. If the number of available hours for production (discounting maintenance time for machines, lunch and breaks for people, and so on) for the resource is equal to or less than the hours demanded, then we know we’ve found our Herbie.

Getting a fix on the total market demand is a matter of pulling together data which we have on hand anyway—the existing backlog of customer orders, and the forecast for new product and spare parts. It’s the complete product mix for the entire plant, including what we "sell’’ to other plants and divisions in the company.

Having done that, we’re now in the process of calculating the hours each "work center’’ has to contribute. We’re defining a work center as any group of the same resources. Ten welders with the same skills constitute a work center. Four identical machines constitute another. The four machinists who set up and run the machines are still another, and so on. Dividing the total of work center hours needed, by the number of resources in it, gives us the relative effort per resource, a standard we can use for comparison.

Yesterday, for instance, we found the demand for injection molding machines is about 260 hours a month for all the injection molded parts that they have to process. The available time for those machines is about 280 hours per month, per resource. So that means we still have reserve capacity on those machines. But the more we get into this, the more we’re finding that the accuracy of our data is less than perfect. We’re coming up with bills of material that don’t match the routings, routings that don’t have the current run-times—or the correct machines, as we just found out—and so on.

"The problem is, we’ve been under the gun so much that a lot of the updating has just fallen by the wayside,’’ says Stacey. "Hell, with engineering changes, shifting labor around, and all that happening all the time, it’s just plain tough to keep up with it no matter what,’’ says Bob.

Ralph shakes his head. "To double-check and update every piece of data relevant to this plant could take months!’’ "Or years,’’ mumbles Bob.

I sit down and close my eyes for a second. When I open my eyes, they’re all looking at me.

"Obviously, we’re not going to have time for that,’’ I say. "We’ve only got ten weeks now to make something happen before Peach blows the whistle. I know we’re on the right track, but we’re still just limping along here. We’ve got to accept the fact we’re not going to have perfect data to work with.’’

Ralph says, "Then I have to remind you of the old data processing aphorism: Garbage in, garbage out.’’

"Wait a minute,’’ I say. "Maybe we’re being a little too methodical. Searching a data base isn’t the only way to find answers. Can’t we come up with some other faster way to isolate the bottleneck—or at least identify the candidates? When I think back to the model of the boys on the hike, it was obvious who the slower kids were on the trail. Doesn’t anybody have any hunches where the Herbie might be in the plant?’’

"But we don’t even know if we’ve got one yet,’’ says Stacey.

Bob has his hands on his hips. His mouth is half open as if he might say something. Finally, he does.

"Hell, I’ve been at this plant for more than twenty years. After that much time, I know where the problems usually seem to start,’’ he says. "I think I could put together a list of areas where we might be short on capacity; at least that would narrow the focus for us. It might save some time.’’

Stacey turns to him. "You know, you just gave me an idea. If we talk to the expeditors. They could probably tell us which parts they’re missing most of the time, and in which departments they usually go to look for them.’’

"What good is that going to do?’’ asks Ralph.

"The parts most frequently in short supply are probably the ones that would pass through a bottleneck,’’ she says. "And the department where the expeditors go to look for them is probably where we’ll find our Herbie.’’

I sit up in my seat. "Yeah, that makes a lot of sense.’’

I stand up and start to pace.

"And I’ll tell you something

I

just thought of,’’ I say. "Out on the trail, you could tell the slower kids by the gaps in the line. The slower the kid, the greater the distance between him and the kid in front of him. In terms of the analogy, those gaps were inventory.’’

Bob, Ralph, and Stacey stare at me.

"Don’t you see?’’ I ask them. "If we’ve got a Herbie, it’s probably going to have a huge pile of work-in-process sitting in front of it.’’

"Yeah, but we got huge piles all over the place out there,’’ says Bob.

"Then we find the biggest one,’’ I say.

"Right! That’s got to be another sure sign,’’ says Stacey.

I turn and ask, "What do you think, Ralph?’’

"Well, it all sounds worth a try,’’ says Ralph. "Once you’ve narrowed the field to maybe three of four work centers, it won’t take long for us to check your findings against the historical data just to be sure.’’

Bob looks at Ralph and says in a kidding voice, "Yeah, well, we’ve all seen how good that is.’’

But Ralph doesn’t take it in a kidding way. He looks embarrassed.

"Hey, I can only work with what I’ve got,’’ he says. "What do you want me to do?’’

"Okay, the important thing is that we have new methods to try,’’ I say. "Let’s not waste time pinning the blame on bad data. Let’s get to work.’’

Fueled by the energy of new ideas, we go to work, and the search goes quickly...so quickly, in fact, that what we discover makes me feel as though we’ve run ourselves straight into a wall.