The Dawn of Innovation (36 page)

Read The Dawn of Innovation Online

Authors: Charles R. Morris

Corliss marketed his machine in the early days by offering customers an option of a fixed price or a sum geared to actual fuel savings. Customers who chose the contingent price always paid much more. Fuel savings were even higher than raw fuel consumption data suggest, because the intrinsic regularity of the operation allowed the use of lower-quality coals. Textile mill operators most valued the “extreme regularity” of the Corliss. The reductions in thread breakage made it almost a must-have in the industry. In its first fifteen years of operation, up to 1862, the company sold 480,000 horsepowers, or about 480 separate engines. (At the time, engines were only about 30 percent of its sales.) Sales over the next seven years more than doubled the installed horsepower, reflecting both sales growth and a trend toward larger engines. By the time his patents expired in 1870, Corliss had collected $213,000 just in royalties, mostly from his own company.

Corliss's great success was marred by bitter and prolonged patent litigations. In truth, almost every important feature of his engine had been anticipated by previous patents, although none had presented a comprehensive, integrated, new plan for an engine the way Corliss had. In later patent filings, he acknowledged the priority of other designers for specific pieces, although the designs themselves were quite different. While he didn't win every caseâhe bemoaned the unpredictability of lay jurorsâhe carried all the essential ones, and Congress granted him a seven-year extension to compensate for his loss of revenue while the litigations were underway.

Corliss's most famous engine was produced as the showpiece for the 1876 centennial celebration in Philadelphia. It was an unreserved bash, attracting 10 million visitors from all over the world with some 30,000 exhibits spread over 236 acres in Fairmount Park. But the center of attraction was the goliath Corliss steam engine powering thirteen acres of machinery in Machinery Hall. It comprised two one-cylinder walking-beam engines. The beam centers were 30 feet off the floor; the beams themselves were 27 feet long and 8 feet deep at their center. The cylinder was more than 3 feet in diameter, and the great flywheel weighed fifty-six tons. Visitors were most impressed, however, by the machine's near silence, which attests to the very high quality of manufacturing at Corliss. The power shaft driving the Hall's machinery was 352 feet long, and its major distributing gears were all 6-foot-diameter bevel gears. The trueness of the drive shaft and the lack of chatter in the enormous gears exemplified the precision of Corliss's products.

Unlike a Baldwin, Corliss usually made

every

part in his own factory, which had been constructed to build to monumental size. Besides his engines, he made a wide range of heavy machinery and parts, like heavy wheel and shaft castings. His plant could pour single castings of as much as thirty-two tons. There were also four in-plant locomotive turntables with two railroad spurs connecting to commercial lines. (A locomotive could enter the plant, take a load, and be turned around on the table.) A fair summary of the Corliss operation is that it was one of the world's best

British-style heavy manufacturing operations, working on a craft basis at every stage of production.

every

part in his own factory, which had been constructed to build to monumental size. Besides his engines, he made a wide range of heavy machinery and parts, like heavy wheel and shaft castings. His plant could pour single castings of as much as thirty-two tons. There were also four in-plant locomotive turntables with two railroad spurs connecting to commercial lines. (A locomotive could enter the plant, take a load, and be turned around on the table.) A fair summary of the Corliss operation is that it was one of the world's best

British-style heavy manufacturing operations, working on a craft basis at every stage of production.

In the mid-1880s, Corliss closed down his plant with the thought of converting it to a more mechanized, assembly-line-type operation, but he died suddenly in 1888, at the age of seventy-two, and the plans were never implemented. The business declined after his death, for he had not provided for a successor. One of his great engineers, Edwin Reynolds, had joined the E. P. Allis Company of Milwaukee (later Allis Chalmers) in 1877, after serving as Corliss's general superintendent for six years. With Corliss gone, Allis became the leader in innovation in very heavy machinery. By then, nearly the whole industrialized world had converted to Corliss-type machines for heavy steam plants, until they were superseded by the steam turbine and new valve configurations around the period of the First World War.

Hoe PrintingRobert Hoe, an apprentice carpenter, emigrated from England to the United States in 1803, when he was nineteen. In New York City, he and two brothers-in-law, a joiner and the inventor of a hand press, formed a company to make wooden presses and later saws. After his brothers-in-law died, Hoe continued the firm under the name of R. Hoe & Co. When he died in 1833, he was succeeded by his eldest son, Richard March Hoe, who became one of the great figures in nineteenth-century printing technology.

58

58

Hand printing presses had changed little since the days of Gutenberg, and the conventional designs were maintained through the early generations of power-driven presses. A bed of typeâthe formâwas inked, and then a piece of paper held tightly in a frame was forcefully pressed into the form by a flat metal or wood platen. Thus the first powered cylinder press, invented by a Saxon, Friederich Koenig, and installed at the London

Times

in 1814, was something of a landmark event. In Koenig's machine the set type lay flat and was moved back and forth. A cylinder held the paper sheet and had three positions: one for loading the sheet, one for the actual

printing, and one for removing the sheet. Sheet loading and removal was by hand, but with skilled feeders the presses could produce up to four hundred pages an hour. The machine was widely adopted by the British, who made a number of improvements, especially in the paper handling.

59

Times

in 1814, was something of a landmark event. In Koenig's machine the set type lay flat and was moved back and forth. A cylinder held the paper sheet and had three positions: one for loading the sheet, one for the actual

printing, and one for removing the sheet. Sheet loading and removal was by hand, but with skilled feeders the presses could produce up to four hundred pages an hour. The machine was widely adopted by the British, who made a number of improvements, especially in the paper handling.

59

The Hoes learned about the cylinder press only in 1832, when the senior Hoe was already ill. Richard produced his own version in 1833 and sold them by the hundreds. By the 1840s, his double-cylinder press achieved speeds of 4,000 pages per hour on one side, with two feeders.

The cost of paper fell rapidly after the introduction of the Fourdrinier paper-making machinery from France. In the world's most literate and information-hungry nation, cheap paper was like crack cocaine; the bottleneck was only the speed of the presses. Hoe's response was the patented Hoe Type Revolving Machine. Instead of a flat bed of type with the paper turning on a cylinder, Hoe put the

type

on a large central cylinder, with the paper fed in flat and taken up by a stationary roller. The major technical challenge was learning how to fix the type securely in the form of a nearly perfect circle.

type

on a large central cylinder, with the paper fed in flat and taken up by a stationary roller. The major technical challenge was learning how to fix the type securely in the form of a nearly perfect circle.

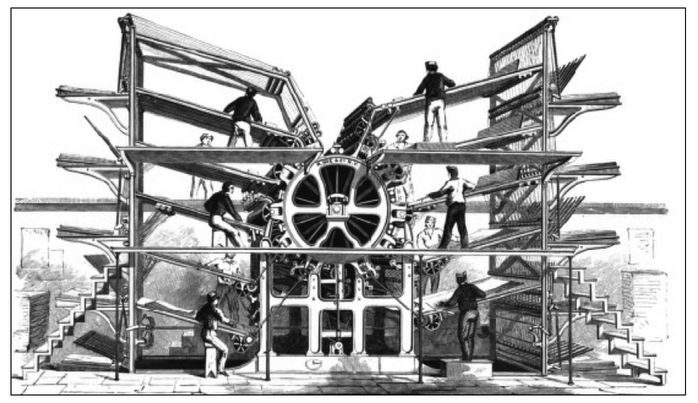

The new machine incorporated a number of important paper-handling improvements: the feeder simply slid the sheets down a ramp, and mechanical contrivances positioned them correctly on the roller, unloaded them after printing, and stacked them in the correct piles; the inking apparatus was built into the central cylinder. The beauty of the arrangement was that one could position a number of separate feeding slots and printing rollers around the central roller. The biggest, and fastest, model sold was the Ten Cylinder model shown on page 235, with feeders positioned on both sides.

The Ten Cylinder machine achieved output of 20,000 pages an hour and was an essential enabler of the vast proliferation of newspapers of all kinds in the mid-nineteenth century. Most of the large presses in the world adopted the Hoe revolving press. Great Britain was the sole holdout, until the London

Times

finally purchased two Ten Cylinder presses in 1856. That was an especially sweet victory for the Hoes, for in 1848, when the

Times

purchased a conventional press, it had pointedly editorialized on the absurdity of the Hoe claims: “No art of packing could make the type adhere to a cylinder revolving around a horizontal axis and thereby aggravating centrifugal impulse by the intrinsic weight of the metal.”

Times

finally purchased two Ten Cylinder presses in 1856. That was an especially sweet victory for the Hoes, for in 1848, when the

Times

purchased a conventional press, it had pointedly editorialized on the absurdity of the Hoe claims: “No art of packing could make the type adhere to a cylinder revolving around a horizontal axis and thereby aggravating centrifugal impulse by the intrinsic weight of the metal.”

Â

Hoe Ten-Cylinder Printer.

Printing presses achieved very high speeds when Richard Hoe managed to create a cylindrical type holder that could retain the heavy type at a high rate of rotation. The inking apparatus was inside the cylinder, so fresh newsprint could be introduced at multiple points on the cylinder. Young boys could serve as feeders, since advanced paper-handling apparatus made the final paper placements. Note that six feeders are working on the near side of the machine and four on the other.

Printing presses achieved very high speeds when Richard Hoe managed to create a cylindrical type holder that could retain the heavy type at a high rate of rotation. The inking apparatus was inside the cylinder, so fresh newsprint could be introduced at multiple points on the cylinder. Young boys could serve as feeders, since advanced paper-handling apparatus made the final paper placements. Note that six feeders are working on the near side of the machine and four on the other.

Not much is known of the details of Hoe's manufacturing processes, but what is known suggests that they ran rather as Baldwin's did. All makers of heavy equipment were necessarily major uses of power-assisted machinery, much of it made in their own factories, as it was with Baldwin and Corliss. Precision requirements were increasing in all branches of industry, and a machine like Hoe's Ten Cylinder press included thousands of small parts and had to be exquisitely calibrated to maintain proper print registers at speed. Hoe also developed its own large-form depthing micrometer for precise manufacturing measurements, which put them in the forefront of the gauging movement.

60

Because of their scale and complexity, major products did not lend themselves to mass-production engineering.

Like a locomotive, each big press would be custom-built, but with considerable standardization of key parts to simplify servicing and maintenance.

60

Because of their scale and complexity, major products did not lend themselves to mass-production engineering.

Like a locomotive, each big press would be custom-built, but with considerable standardization of key parts to simplify servicing and maintenance.

R. Hoe & Co. was a dominant player in large-scale printing through the rest of the century; among its many other innovations, it invented the first newspaper-folding presses. Almost weirdly, it never dropped the saw business that the senior Hoe and the Smiths had picked up in the company's earliest days. Mocking any business-school notion of “focus,” Hoe was a major competitor in large industrial saws well into the twentieth century.

61

61

B

UT THE NORTHEAST WAS HOME TO ANOTHER STREAM OF INDUSTRIAL development : the true armory practice tradition of mass production of complex, high-precision products, with special-purpose machinery and high-precision hand finishing to such a level of accuracy that parts can be freely interchanged from one unit to the other. In mid-century, the exemplar of armory practice was Samuel Colt's great gun-making plant in Hartford. The British discovery of Colt and of armory practice manufacturing, and their decision to purchase American arms-making equipment for their own military, marked the first recognition by influential Britons that the United States was proceeding about its business in some quite original ways.

UT THE NORTHEAST WAS HOME TO ANOTHER STREAM OF INDUSTRIAL development : the true armory practice tradition of mass production of complex, high-precision products, with special-purpose machinery and high-precision hand finishing to such a level of accuracy that parts can be freely interchanged from one unit to the other. In mid-century, the exemplar of armory practice was Samuel Colt's great gun-making plant in Hartford. The British discovery of Colt and of armory practice manufacturing, and their decision to purchase American arms-making equipment for their own military, marked the first recognition by influential Britons that the United States was proceeding about its business in some quite original ways.

CHAPTER SEVEN

On the Main Stage

Other books

White Winter (The Black Year Series Book 2) by D.J. Bodden

A Haunted Romance by Sindra van Yssel

Sting by Jennifer Ryder

Scored by Lauren McLaughlin

Wolf Wood (Part Two): The Dangerous years by Mike Dixon

Macy’s Awakening by Anthony, Pepper

Barefoot Pirate by Sherwood Smith

Trigger by Courtney Alameda

Resurrection House by James Chambers