Indian Innovators (15 page)

During the presentation, we were quizzed on several aspects of our work. We had printed a few business cards on our paper to present to the judges. They could not believe that it was not normal paper. They tried writing on it, dipped it in water and even tore it to check the strength.

We could easily address the queries on the technical aspects, but had little idea about the business aspects. We had never made a formal business plan. Because the investors were primarily interested in the business strategy and market potential, we were pretty confident that this was the end for us.

When the results were announced, to our great surprise, we found ourselves placed second. We received 30,000 as cash prize, but more importantly, we gained a lot of confidence. It dawned on us that we were doing great work and it was worth pursuing with even more vigor.”

30,000 as cash prize, but more importantly, we gained a lot of confidence. It dawned on us that we were doing great work and it was worth pursuing with even more vigor.”

The team then applied to the DST—Lockheed Martin India Innovation Growth Program 2013 and was selected among the top 50 from across the country. “We were offered a week-long grooming workshop on technology commercialization and entrepreneurship before the final presentation. The workshop was held in Goa in April 2013, under the tutelage of faculty from Stanford Business School. It was extremely useful while facing the international panel of judges at the competition. We perfected our pitch for investors and got to interact with and learn from fellow participants.

We performed better than our expectations at the competition and were awarded a gold medal and a cash prize of 1 lakh. We were also offered an opportunity to go to Silicon Valley, along with nine other teams, to interact with investors and technologists there.

1 lakh. We were also offered an opportunity to go to Silicon Valley, along with nine other teams, to interact with investors and technologists there.

The catch was that only one of us could go to Silicon Valley. We were a bit dejected, because it would be unfair for only one of us to go when all of us had worked on the technology.”

However, the teammates nominated Anurag to go on their behalf.

“The team members said that any one of them being there was as good as every one of them being there, because the learning would eventually be passed onto others as well. Their selflessness was inspiring and made us stronger as a team,” Anurag says.

However, the journey to the US was not as smooth as expected, he recalls. “I was to fly from Bhubaneswar to Delhi at 2 PM on August 24, 2013, to catch a flight to San Francisco on the night of the 24th. There was no news of the visa until the day before. I was very worried, but was in constant touch with the concerned people at FICCI, who were trying to do everything possible at their end. I received a call from the US consulate at 12:30 PM on the 24th; my passport was ready to be collected with the visa stamped, with just one-and-a-half hours remaining for my flight to Delhi. I immediately cancelled the ticket and FICCI booked another flight for me, scheduled to leave Bhubaneswar at 7 PM.

Because I had not been sure of getting the visa on time, I was yet to pack my bags. I rushed to my hostel and packed whatever clothes I had into a bag. I did not have many warm clothes, because Bhubaneswar is not as cold as San Francisco, but that was the last thing on my mind. I rushed directly to the airport after collecting the passport and was just in time for my flight to Delhi. It was my first flight ever and I was to fly almost continuously for the next 24 hours.”

The journey was completely worth the anxiety, Anurag discovered. “The reception in Silicon Valley was amazing. We were being hosted by Stanford as a part of the Stanford Global Innovation Program and there were young innovators from around the globe. The program had been running for the last few years and we were the first batch of participants from India.

There were so many events planned for us and the treatment was simply outstanding. For the first time, I realized that innovators could earn so much respect and recognition.

We were also taken to the campuses of Google, NASA and several technology start-ups and incubators, so that we could learn from the start-up culture in Silicon Valley. We got to interact with a lot of Indian technopreneurs via the Silicon Valley chapter of TiE. It was a truly amazing experience.

After returning, our team got felicitated by our university. We were offered incubation at the technology incubator within the university. The local media also praised us.

There is now a big shift in the attitude of students at our university toward research. Earlier, nobody did any projects or internships. Now, they are so inspired that almost everyone seems to be seeking to do a research project.”

Anurag shares the team’s future plans. “Currently, we are trying to scale up paper production from the laboratory to industrial scale. There are challenges involved in scaling up, such as loss of efficiency, that is, lower yield and increased duration of the process. We are trying to fix those issues now.

We are also working toward modeling the business as B2B rather than B2C, that is, supplying pulp to paper- making companies, rather than making paper and paper products and selling those to the end user.

We hope our efforts bear fruit and we are able to hit the market as soon as we complete our engineering degree.”

For the Innovator in You

“All you can do is try your level best and leave everything else to God. Sometimes things work out, sometimes they do not, but you should learn from both success and failure. Do not be disappointed by failures. Remember what Thomas Edison said in response to the question on how he felt after failing 100 times before inventing the light bulb – ‘It was not 100 failures; it was a 100-step process’.”

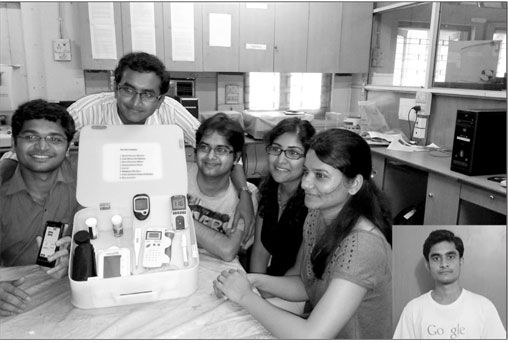

CareMother Team with the kit – (L to R) Shantanu Pathak, Swapnil Kokade, Vaibhav Tidke, Dr Shital Somani, Dr Shital Munde and Aditya Kulkarni (inset)

CareMother Testing Kit and Digital Platform for Providing Pregnancy Care

India holds the dubious distinction of having the highest number of pregnancy-related deaths in the world each year. According to a 2010 UN report, 19% (that is, almost 1 in 5) of global pregnancy-related deaths happened in India. This means that 56,000 mothers die in India every year, that is, 150 every day.

The gravity of the situation can be understood by looking at the next four countries on the list of pregnancy-related deaths by country: Nigeria – 14%, Democratic Republic of Congo – 5%, Pakistan – 4% and Sudan – 3.5%.

The maternal mortality rate, that is, the number of maternal deaths per 100,000 live births, stands at 200 for India. The same number is 50 times lower for Italy at just 4. Even China, with comparable demographic and economic status, has a much lower rate – 45 deaths per 100,000 live births.

The leading causes of maternal mortality include high blood pressure during pregnancy, severe bleeding and infections. Most of these complications can be avoided or handled without loss of life, if there is regular monitoring of high-risk pregnancies and timely medical aid is made available in emergency situations.

Unfortunately, despite several rural health schemes, access to good medical infrastructure and trained medical practitioners is limited to the cities. Mothers in rural parts of the country still have poor access to healthcare.

However, where the government has failed, a few young technologists are determined to make a difference.

Shantanu Pathak, an electronics engineer, started an informal group in 2008 called Science for Society; the aim was to bring together like-minded people to develop technologies for solving basic social problems. At that time, he was a second-year student at Lokmanya Tilak College of Engineering, Navi Mumbai.

From the beginning, the group’s focus was to bring in people from different backgrounds to conduct interdisciplinary product-related research. As a result, a most unusual mix of people came together to create the most unusual results.

While his teammates were away, presenting their invention at a conference in Pune, Shantanu took me through the inspirational journey of Science for Society.

“Initially, Science for Society began as an NGO. Anybody who had a passion for technology and wanted to use his knowledge for the greater good was welcome. Some people contributed ideas and others helped with the execution. There were those who worked for a short time and those who stayed forever.

Among those who swore their permanent allegiance to Science for Society were Swapnil Kokade, Vaibhav Tidke, Aditya Kulkarni, Dr Shital Somani and Dr Shital Munde.

In the beginning, the focus was more on renewable energy. We designed some manually powered LED lighting devices and a manually driven UV disinfection system for water purification. Water purification kits were even installed in a few rural schools. We also made a solar- powered conduction dryer to dehydrate fruits and vegetables and increase their shelf life, thereby saving at least 33% of seasonal agro-products in areas that do not have access to reliable electricity. We were awarded the Mondialgo Engineering Award in 2009 for the dryer by Daimler AG (the manufacturers of Mercedes cars) in association with UNESCO. We were invited to Stuttgart, Germany to receive the award worth 20,000 euros.

Another solar-energy-based device we made during this period was an egg incubator, which not only saved the cost of electricity, but was also eight times cheaper as compared to the conventional electric egg incubator.”

The team obtained patents for each of those devices.

The team’s focus soon shifted to healthcare.

Shantanu describes the team’s motivations. “I always wanted to do something in healthcare. I come from a very small town called Risod, located in the Washim district of Maharashtra. I lost my father when I was just 12 years old. It happened suddenly and the doctors could never ascertain the reasons. Despite the era of economic hardships that followed, my elder brother and mother ensured that I got the best education possible. I always felt that if my father could have had regular health checkups, he would probably be alive today. Thus, I wanted to do something to improve healthcare access for the masses. My other teammates were also from small towns and they, too, felt strongly about rural healthcare access.

Dr Shital Somani is a dentist; she suggested we work on an automated dental X-ray machine. Because the oral cavity is comprised of bony and soft tissues, dental treatment needs an X-ray for diagnosis at all stages of the treatment process. All dentists have their own dental X-ray setup, and roughly 200,000 dental X-rays are taken in India every day. In order to develop the X-ray films, a series of dark-room chemical reactions need to be performed manually. The process is time-consuming and requires frequently changing chemicals; still, the quality of films is inconsistent. The aim was to automate the dental X-ray processor, so that it reduces time taken and chemical usage and results in better quality of films.

A few imported X-ray processors are available in the market, but they cost between 50,000–300,000 and every Indian dentist cannot afford them. These machines also have maintenance problems and are bulky, making them unsuitable for rural mobile clinics.

50,000–300,000 and every Indian dentist cannot afford them. These machines also have maintenance problems and are bulky, making them unsuitable for rural mobile clinics.

Thus, the challenge was to make a portable, almost zero-maintenance, low-cost device.

X-ray processing is a solid–liquid multiphase reaction process. Keeping this in mind, we designed a novel solid fluid reactor that uses only the optimum amount of chemicals. The reactor was also provided with a vibrator to carry out uniform mixing and accelerate the rate of reaction. A series of chemical reactions and drying are carried out in a sequential manner and the entire process is controlled by a microcontroller. We also used an air exclusion chamber to prevent oxidation and contamination.”

Shantanu states that these innovations helped them achieve a reduction of 75% in the consumption of environmentally hazardous chemicals. Moreover, it was possible to use the machine in a non-air conditioned or dusty environment. The machine did not use any moving parts and required so little energy that it could be operated on a battery of modest capabilities. Thus, it was easy to maintain and did not need electricity to work.

“Its cost worked out to be just 5,000 and it did not require any trained labor to operate,” Shantanu adds.

5,000 and it did not require any trained labor to operate,” Shantanu adds.

“The project received a lot of attention and appreciation. We were featured in the Dell Social Innovation Challenge in 2010 and applied for a patent soon thereafter.”

By this time, Shantanu had completed his graduation. “I was sure I wanted to keep inventing something to make lives better for the underprivileged. At the same time, it was a reality that I needed a job to save enough to put into my experiments and also to support my family.

I really liked telecommunications; so, I took up a job with a Chinese telecom equipment manufacturer, ZTE Telecom. The job required me to relocate to Shenzen, China. Shital joined a management program in Mumbai and got married. Aditya moved to the Indian Space Research Organization (ISRO) for a job and eventually to National University of Singapore to pursue a PhD program in Computer Science. Vaibhav and Swapnil were still pursuing their respective programs at the Institute of Chemical Technology (ICT), Mumbai.”

The future of Science for Society was uncertain at this point. “We had some really good technologies, but some of the people who had worked on the projects had left and we were not sure if we should commercialize the technologies without them. Moreover, we were not really business-oriented.

Despite being in different parts of the world, we kept in touch via the internet. Around the same time, Dr Shital Munde’s elder sister got pregnant. Her last two pregnancies had ended in miscarriages, first due to high blood pressure (gestational hypertensive disorder or pregnancy induced hypertension) and the second due to excessive bleeding. This time too, it was a high-risk pregnancy.

Shital, being a doctor herself, started recording the blood pressure and urinary protein levels every six hours, which is the standard practice in such cases. The process was uncomfortable, because the samples needed to be taken to a pathology laboratory every few hours.

In one of our brainstorming sessions, we realized that Shital’s sister was lucky that she had a doctor in the family and could be monitored 24×7. Many others were not as fortunate, for they either did not have access to a doctor or could not afford frequent testing and medical consultations.

When we came across the statistics on maternal mortality, we were absolutely determined to do something about it.

We figured out that there were two parts to the problem. First, to make a portable non-invasive testing kit which could save the patient the trouble of going to a lab for testing and allow any untrained person to record the readings; and second, to make the patient’s test results accessible to a doctor, who could then advise the patient accordingly.”

The team began on the hardware first. “We divided the responsibilities and started working from wherever we were, conducting meetings and discussions online. We focused on our respective jobs or academics in the day and worked late into the night on the project. The experience with telecom equipment came handy during this time.

We wanted to make sure the kit could test all the key pregnancy-related parameters, and yet, be light and inexpensive. Some of the instruments available were already quite portable, but others were not. Also, some were too expensive. We had to redesign some of the testing equipment to make it lighter or cost-effective. For instance, the weighing scale itself weighs about half a kilogram and is difficult to carry around. We had to redesign it to fit into the box of the kit; we also ensured that the whole kit, weighing scale included, did not weigh more than a couple of kilograms. Usually, the fetal heart rate (FHR) meter takes up to 10 minutes to give a reading, which consumes a lot of battery. We designed the FHR meter in our kit to give a reading in just a couple of minutes, so the battery lasts longer.

As the work on this project increased, we realized its potential in ushering a healthcare revolution in many developing countries. We started considering pursuing this project full-time and devoting ourselves to taking it to the market.”

After a year with ZTE in China, Shantanu resigned from the job. He decided to come back to India and pursue activities at Science for Technology full-time.

“In 2011, we incorporated Science for Society as a company by the name of Science for Technology Techno-Services Pvt Ltd and took up a small office in Dadar. The project got a name – CareMother, and we started developing an app to link the patient with the doctor. At the same time, we started work on a business model in order to make it commercially viable.

During that time, in order to support ourselves, some of us did tuitions and other part-time jobs, but we did not let the work suffer.

We did an extensive ground survey to identify the pain points, ascertain the features that would be useful for end users and price points the users were comfortable with. It took us about ten months to get the app and business plan ready.”

This is how CareMother works. The community health worker can take the portable CareMother kit to the patient’s home and conduct vital pregnancy-related tests, such as weight, height, temperature, blood pressure, blood hemoglobin, FHR and fundal height (the size of the uterus, which is used to assess fetal growth and development during pregnancy; it is measured in centimeters, from the top of the mother’s uterus to the top of her pubic bone). The health worker then enters the data into the CareMother app and saves it. The data is uploaded automatically to the CareMother server as soon as an internet connection is available.