Hank Reinhardt's Book of Knives: A Practical and Illustrated Guide to Knife Fighting (13 page)

Read Hank Reinhardt's Book of Knives: A Practical and Illustrated Guide to Knife Fighting Online

Authors: Hank Reinhardt

A pocket clip can help make for a fast and smooth draw from your pocket.

The only disadvantage is that there are times you do not want anyone to see you have a pocket knife. The answer is simple: remove the pocket clip (easily done with a small screwdriver) or you can simply leave the pocket clip on but let the knife rest in your pocket. Try both methods and see what works best for you.

I know I am sounding like a salesman for Saul Glasner, but with a combination of the pocket clip and the wave feature, you can even draw your knife from a seated position. Once again, ladies and gents, this does take practice. But to date this is the fastest gadget I’ve seen to get a knife out of your pocket lickety-split.

The whole point of a knife is its edge (no pun intended), of which there are basically only two types: serrated and smooth. There are a lot of advantages to a serrated blade. It rips through a lot of material even wet stuff, wet rope, or seat belts—this is where serrations really shine. The biggest disadvantage is limited life expectancy; they can only be sharpened a few times, then they lose their effectiveness. I cannot tell you how many knives I have ground the serrations off of, and put a straight edge on, to extend the life of the knife. When you pay over forty dollars for a knife, you want to get as much use out of it as you can.

The other disadvantages of serrations include that they are hard to sharpen and that the cut of a serrated knife is not as smooth as those of a straight edge, especially if the serrations are dull.

Then we have the worst of both worlds, the half-serrated and half-straight, the knife which cannot make up its mind. This is how you can take a perfectly good design and get a knife that won’t do well at any task. In addition, it is a hair-pulling operation to sharpen. So either get your knife serrated or with a straight edge. Don’t buy one in a state of confusion.

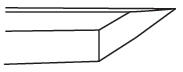

BLADE GEOMETRY

Now for blade geometry. Basically a knife is a wedge. If it’s too thin, it will wedge in the material. If it’s too thick, it won’t penetrate the material. You might have an extremely sharp edge with a hollow ground profile. The disadvantage here is the more you sharpen it, the less hollow ground it becomes. We know pocket knives are thin, but you would be surprised how much better they cut with the right geometry.

Plus, a hollow grind on a knife results in a not very strong shape. It chips easily and can develop cracks which will create breaks. I once saw a high quality hollow ground pocket knife that had about two inches of the blade gone. Somebody had cut an individual in a denim jacket. He hit a button on the jacket and lost two inches of blade on a pocket knife which was not very large to begin with. The remaining blade didn’t give him much to work with. Instead of a hollow grind, we need a shallow “V” shaped blade with not a whole lot of really sharp point. But the point needs to be as strong as the edge: remember, your opponent may have change in his pocket or ball point pens, or a coat with heavy buttons or zippers. The point needs to be strong enough to hit these items and still skate off to puncture him. Trouble is, it’s difficult to find a pocket knife with a strong point. They are naturally thin by nature. Pick designs with the strongest points.

Side and point-on views of a strong point (above) and a weak point (below).

TESTING THE CUTTING EDGE

Nowadays, almost any brand of pocket knife you buy is shaving sharp right out of the box. Of course, as with all weapons, you still need to check the edge to make sure it is that sharp. This needs to be done carefully, and I must emphasize,

really,

carefully.

Take the knife, put it on your arm, raise it to a 45-degree angle with blade just touching the skin, then carefully push the knife towards your hand in a shaving motion. This takes practice.

If the knife is truly sharp, the hair should literally jump off your arm. As a self-defense pocket knife, your weapon should be this sharp at all times. The first time I ever saw a shaving-sharp pocket knife, Hank was cutting off a shoelace that had gotten frayed. He literally touched it and cut through it. This is one of those you-had-to-be-there things. I told Hank I had never seen anything cut that quickly. At this point Hank said, “Let me show you something.” We went to the bathroom and Hank lathered up just below one of his uneven sideburns. Then he proceeded to shave his face to even up that sideburn. That knife was as sharp as my grandfather’s straight razor.

I asked Hank if he could show me how to make my knife that sharp. He said he would show me, but that if I cut myself I shouldn’t “come crying to him.” That same day I brought over my prized possession, a small four-inch bladed Case sheath knife. After much trial and error, I was able to get that knife so that it would shave hair off my arm.

I used to think this was as sharp as you could get a knife. That was until Jimmy Fikes, a nationally known bladesmith, returned to the Birmingham area, and showed me a whole new level of sharpness. I can now take a paperback book and cut the ends off that book by simply pressing down with hand pressure.

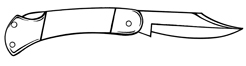

The knife world is really in love with the new, different, and exotic. As with serrations, the tanto point has become all the rage. This is rather amazing and got me considering that the Japanese knife we know as “tanto” does not have this point style.

The point of an actual Japanese tanto (above) is not what we call a tanto point now (below).

If you look at the rounded point of most pocket knives, you will see they have basically the same cutting effect as the tanto point. There are those who say that it will penetrate better than other point styles, better than a round style knife. You can easily discover the truth by doing the old stab-the-phonebook test. You’ll find that the tanto point penetrates no deeper than the round point style. If you want a sexy and svelte pocket knife, by all means get a tanto point but don’t expect it to perform any better than Grandad’s point style.

In the twenty-first century, most new knives will be shaving-sharp when you get them. If a blade is this sharp and will cut easily through a small paperback book, no more sharpening is necessary. However, part of this job is mental. You must think of your pocket knife as a weapon, not a tool. You can cut a little string here, cut a cardboard box there, maybe open up a package, and your edge is no longer shaving sharp. I suggest you don’t use your knife as a tool. That way your edge is always ready to defend your honor.

STEEL

Current steels are an important subject. Just a few years ago most stainless steel pocket knives had some of the poorest edge-holding qualities this side of a junk yard.

I had a name brand pocket knife given me by a friend. After sharpening a pencil, it would go from hair-flying sharp to so dull that you could apply pressure on the edge with your thumb and it would not even bite the skin. Now, there are several specialty melts of stainless steel that now hold an excellent edge. I recently tested a Cold Steel pocket knife that cut a hundred pieces of half-inch sisal rope, then carved one paperback book into small pieces, and afterwards was still sharp enough to shave hair on my arm. Hopefully one day we will see a production knife that will cut two hundred pieces of one-inch Manila rope, slice a paperback book and then be able to cut the tips off standing hair on my arm. The more the public learns about knife sharpness, the better the quality of knives we will see.

More recently Spyderco and some other manufacturers have been using a stainless steel called VG-10. The edge-holding ability of this stainless has been excellent. I have been able to cut a hundred pieces of half-inch sisal rope and the knife still has a good working edge. I have recently been testing a knife from Diamond Blade. They use a process called friction forging. I was extremely skeptical of this new tempering process, but like the bank robber said to Dirty Harry, “I just gots to know.” This knife was book-cutting sharp right out of the box. The first cut on the rope was so easy I thought I had bought rotten rope. I made three hundred cuts on the half-inch sisal and I was still able to cut the end off a paperback book just using light pressure on the spine of the blade.

I have not used any production knife which will equal this performance. I’m looking forward to seeing larger knives from this company. It just goes to show that the possibility of almost legendary performance can be had from a production knife.