Fordlandia (6 page)

Authors: Greg Grandin

Tags: #Industries, #Brazil, #Corporate & Business History, #Political Science, #Fordlândia (Brazil), #Automobile Industry, #Business, #Ford, #Rubber plantations - Brazil - Fordlandia - History - 20th century, #History, #Fordlandia, #Fordlandia (Brazil) - History, #United States, #Rubber plantations, #Planned communities - Brazil - History - 20th century, #Business & Economics, #Latin America, #Planned communities, #Brazil - Civilization - American influences - History - 20th century, #20th Century, #General, #South America, #Biography & Autobiography, #Henry - Political and social views

CHAPTER 2

THE COW MUST GO

ONE OF THE BOOKS ERNEST LIEBOLD READ IN HIS DELIBERATIONS on where best to grow rubber was

Through the Brazilian Wilderness

, Theodore Roosevelt’s account of his triumphant Amazon expedition, in which he and his son Kermit almost lost their lives charting the unexplored thousand-mile-long River of Doubt. Roosevelt made only passing reference to the contracting rubber economy, mostly to relate the hard-luck life of tappers. But there was one passage that must have caught Liebold’s attention.

In describing his journey to the headwaters of the Tapajós River, Roosevelt observed that the area’s many fast rivers could provide nearly “unlimited motive force to populous manufacturing communities.” Telegraph lines had to be run, followed by railroads, but there were no “serious natural obstacles” to either task. Once communication and transportation had been established, the “right kind” of settlers would arrive, followed by “enterprising businessmen of foresight, coolness and sagacity” willing to put the migrants to work for “an advantage that would be mutual.” And thus would rise a “great industrial civilization.”

1

If anyone could make it happen—or at least if anyone was sure of his ability to make such a vision happen—it would be Henry Ford. When Roosevelt left for Brazil in late 1913, Ford was already well known as the creator of the world’s first affordable, mass-produced automobile. But when he returned in early 1914, the industrialist had been catapulted to the heights of world fame, lauded as a “sociologist manufacturer” who didn’t just attract the “right kind” of worker but assembled them from whole cloth. “The impression has somehow got around,” said the Reverend Samuel Marquis, who for a time headed Ford’s employee relations office, “that Henry Ford is in the automobile business. It isn’t true. Mr. Ford shoots about fifteen hundred cars out of the back door of his factory every day just to get rid of them. They are the by-products of his real business, which is the making of men.”

2

SUCCESS CAME LATE to Ford. Born on a Michigan farm in 1863, he was forty years old when he founded the Ford Motor Company in Detroit, forty-five when he introduced the Model T, and fifty when he put assembly line production into place and began to pay workers a wage high enough to let them buy the product they themselves made. So while he came of age during the early stages of the Industrial Revolution, the America he lived in for the first half of his life was still mostly rural, and the changes he helped set in motion came stunningly fast.

Ford didn’t invent the assembly line. He claimed he got the idea of having workers remain at one location and perform a single task from the “disassembly lines” found in Chicago’s and Cincinnati’s slaughterhouses, where butchers hacked off parts as pig and cow carcasses passed in front of them on conveyor hooks. Nor did he conceive the other central idea of modern mass production, that is, making parts as identical as possible to one another so that they would be interchangeable. But Ford did fuse these two ideas together as never before, perfecting the idea of a factory as a complex system of ever more integrated subassembly processes.

Most of this innovation took place in Ford’s new Highland Park plant, opened in 1910 and designed by the architect Albert Kahn, who prior to his work with Ford had been associated with the anti–mass production arts and crafts movement. Located a few miles north of downtown Detroit along Woodward Avenue, the factory was enormous. It was four stories high, 865 feet long, 700,000 square feet in total, holding eight thousand machines, and was dubbed the Crystal Palace for the tens of thousands of windowpanes that bathed its shop floor in radiant sunlight. Highland Park was powered not so much by steam or diesel but, as historian Douglas Brinkley puts it, management’s restless search to “save time, money, and manpower through further mechanization.” Within eighteen months of the introduction in April 1913 of the first assembly line to make flywheels, every major component of Ford’s car was being produced on moving lines, including the final confection of the finished product. Highland Park had become a machine itself, which by the midteens was dedicated to making one cheap yet sturdy thing: the Model T.

3

The economics of Ford-style mass production were demonstrably simple. In 1911–12, it took just under seven thousand Ford workers to make 78,440 Model Ts. The following year, both production and the workforce more than doubled. Then in 1913–14, with the introduction of the assembly line and other innovations, the number of cars the factory produced doubled yet again, while the labor force

decreased

from 14,336 to 12,880 men. At the same time, the cost of manufacturing a Model T continued to decline, which allowed for a reduction in price, which increased demand, which generated more profit, which could be poured back into the factory to synchronize and mechanize production even further, to start the whole process over again. By 1921, Ford had captured more than 50 percent of the American car market, producing more than two million Model Ts a year at a production cost 60 percent cheaper than a decade earlier.

4

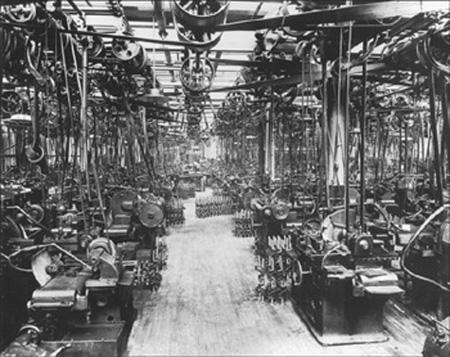

In 1914, the British journalist Julian Street visited Detroit and described the raw energy of Ford’s Highland Park plant:

The whole room, with its interminable aisles, its whirling shafts and wheels, its forest of roof-supporting posts and flapping, flying, leather belting, its endless rows of writhing machinery, its shrieking, hammering, and clatter, its smell of oil, its autumn haze of smoke, its savage-looking foreign population—to my mind it expressed but one thing and that was delirium. . . . Fancy a jungle of wheels and belts and weird iron forms—of men, machinery and movement—add to it every kind of sound you can imagine: the sound of a million squirrels chirking, a million monkeys quarreling, a million lions roaring, a million pigs dying, a million elephants smashing through a forest of sheet iron, a million boys whistling on their fingers, a million others coughing with the whooping cough, a million sinners groaning as they are dragged to hell—imagine all of this happening at the very edge of Niagara Falls, with the everlasting roar of the cataract as a perpetual background, and you may acquire a vague conception of that place.

5

Highland Park’s crankshaft assembly room, 1915

.

For Street, the jungle trope was not to suggest, as it did for Upton Sinclair in his novel about the Chicago meatpacking industry, the anarchic brutality of capitalism, which drains the life out of workers and then casts them off to wither away like so many dead leaves. On the contrary, the British journalist saw the assembly line method as the taming of the industrial jungle, a “relentless system” yielding “terrible efficiency.” “Like a river and its tributaries,” Ford’s integrated assembly lines flowed inexorably to their final destination: a finished Model T.

6

“PEOPLE DON’T STAY put,” Ford once said to explain why communism would never work in the Soviet Union. But neither did they remain still during the first decades of industrial capitalism. At the Ford factory, worker absenteeism averaged 10 percent a day between 1912 and 1913, and the yearly turnover rate of 380 percent was crippling the factory’s production capacity. Ford’s emphasis on synchronization and mechanization only aggravated the already high labor turnover. For the majority of Ford’s ever growing workforce, the slightly better-than-average pay the company offered was not sufficient incentive to be turned into repeating machines.

7

The second stage of Ford’s revolution, then, had to do with human relations, with making people stay put. Ford came to believe that the key to creating loyal, more efficient workers was to help them find fulfillment, as he understood it, outside the factory.

In early 1914, Ford made an announcement that sent seismic shocks across the globe. Henceforth, he proclaimed, the Ford Motor Company would pay an incentive wage of five dollars for an eight-hour day, nearly double the average industrial standard. The

Wall Street Journal

charged Henry Ford with class treason, with “economic blunders if not crimes.” Yet his absentee and turnover rate plummeted and Ford was jolted into the ranks of the world’s most admired men, “an international symbol of the new industrialization.”

8

But high wages alone were not enough to ensure either factory-floor efficiency or individual responsibility. A better salary could just lead to quicker dissipation through gambling, drinking, and whoring. There was no shortage of temptations in iniquitous Detroit. There were more brothels in the city than churches, and workers often lived crowded in fetid slums, in flophouses that fronted for gambling halls, bars, and opium dens. So Ford conditioned his Five Dollar Day plan with the obligation that workers live a wholesome life.

9

And to make sure they did, the carmaker dispatched inspectors from his Sociological Department to probe into the most intimate corners of Ford workers’ lives, including their sex lives. Denounced as a system of paternal surveillance as often as it was lauded as a program of civic reform, by 1919 the Sociological Department employed hundreds of agents who spread out over Dearborn and Detroit asking questions, taking notes, and writing up personnel reports. They wanted to know if workers had insurance and how they spent their money and free time. Did they have a bank account? How much debt did they carry? How many times were they married? Did they send money home to the old country? Sociological men came around not just once but two, three, or four times interviewing family members, friends, and landlords to make sure previous reports of probity were accurate. They of course discouraged drinking, smoking, and gambling and encouraged saving, clean living habits, keeping flies off food, maintaining an orderly house, backyard, and front porch, and sleeping in beds. They also frowned on the taking in of boarders since, “next to liquor, dissension in the home is due to people other than the family being there.”

10

The majority of the Ford Motor Company’s workforce were immigrants, from Poland, Russia, Italy, the disintegrating Austro-Hungarian and Ottoman empires, the Middle East, Japan, and Mexico. In addition to attracting foreign-born workers, Ford’s Five Dollar Day wage sparked a march of African Americans from the South who heard, correctly, that Ford paid equal wages to all male employees, regardless of skin color. The car industry’s absolute need for labor was insatiable in the 1920s and mitigated racism, though African Americans were generally assigned the hardest jobs and the ones with the least potential for advancement. And though ecumenical in his hiring practices, Ford still charged his Sociological Department with Americanizing immigrants, conditioning ongoing employment on their attending English and civic classes. These courses were intentionally mixed by race and country so as to “impress upon these men that they are, or should be, Americans, and that former racial, national, and linguistic differences are to be forgotten.” Commencement from the Ford school had the graduating workers, regaled in their native dress, singing their national songs and dancing their folk dances and climbing up a ladder to enter a large papier-mâché “melting pot.” On the stage’s backdrop was painted an immigrant steamship, and as Ford teachers stirred the pot with long ladles the new amalgamated Americans emerged in “derby hats, coats, pants, vests, stiff collars, polka-dot ties,” singing “The Star-Spangled Banner.”

11

Consider the case of Mustafa, an immigrant who before taking a job with the Ford Motor Company had plowed the fields with his father in Turkey. When he first came to Detroit, he lived in a squalid downtown boardinghouse. Like the rest of his “countrymen,” he washed his “hands and feet five times a day, as part of their religion before praying”—the hygiene of which impressed the sociological inspector less than the time it wasted troubled him (in 1914, Ford had fired nine hundred Orthodox Christians for missing a workday to celebrate Christmas in January). But after passing through Ford’s Americanization programs and moving to “a better locality,” Mustafa “put aside his national red fez and praying, no baggy trousers anymore. He dresses like an American gentleman, attends the Ford English school and has banked in the past year over $1,000.00.” “Let my only son be sacrificed for my boss,” the inspector claimed Mustafa said in gratitude for having had his life turned around. “May Allah send my boss Kismet.”

12

As Ford biographer Robert Lacey put it, the “Five Dollar Day raised the pain threshold of capitalism.” But beyond an incentive to make workers stay put, it also became a model for how to respond to another crisis that plagued industrialism. The mechanized factory production that took flight during America’s Gilded Age had promised equality and human progress but in reality delivered deepening polarization and misery, particularly in sprawling industrial cities like Detroit. Ford, advised by farsighted company executives such as James Couzens and John Lee, understood that high wages and decent benefits would do more than create a dependable and thus more productive workforce; they would also stabilize and stimulate demand for industrial products by turning workers into consumers.